Hill Engineering recently contributed to a publication related to residual stress measurement in additive manufacturing (AM) test specimens titled, Elastic Residual Strain and Stress Measurements and Corresponding Part Deflections of 3D Additive Manufacturing Builds of IN625 AM‑Bench Artifacts Using Neutron Diffraction, Synchrotron X‑Ray Diffraction, and Contour Method. The work was performed under the NIST AM-Bench program in collaboration with researchers from NIST, Los Alamos National Laboratory, University of California Davis, and Cornell High Energy Synchrotron Source. The abstract text is available here along with a link to the publication.

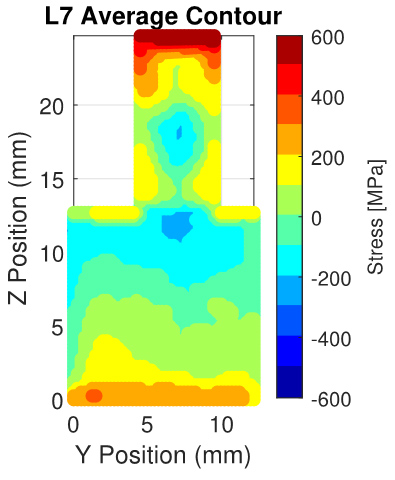

One of the primary barriers for adoption of additive manufacturing (AM) has been the uncertainty in the performance of AM parts due to residual stresses/strains. The rapid heating and cooling rates from the thermal history of the laser melting process result in high residual stresses/strains that produce significant part distortion. Efforts to mitigate residual stresses using post-process heat treatments can significantly impact the microstructures of the AM part which may lead to further issues. Therefore, the ability to accurately predict the residual stresses in as-built AM parts is crucial, and rigorous benchmark measurements are needed to validate such predictions. To fill this need, the AM-Bench aims to provide high-fidelity residual stress and strain benchmark measurements in well-characterized AM bridge-shaped parts. The measurements reported here are part of the residual elastic strain benchmark challenge CHAL-AMB2018-01-RS. Residual strains and stresses in this work were measured using neutron diffraction, synchrotron X-ray diffraction, and the contour method. Part deflection measurements were performed using a coordinate measurement machine after the part was partially separated from the build plate. These independently measured results show a high degree of agreement between the different techniques.

If you are interested, the full publication is available here.

Please contact us for additional information.

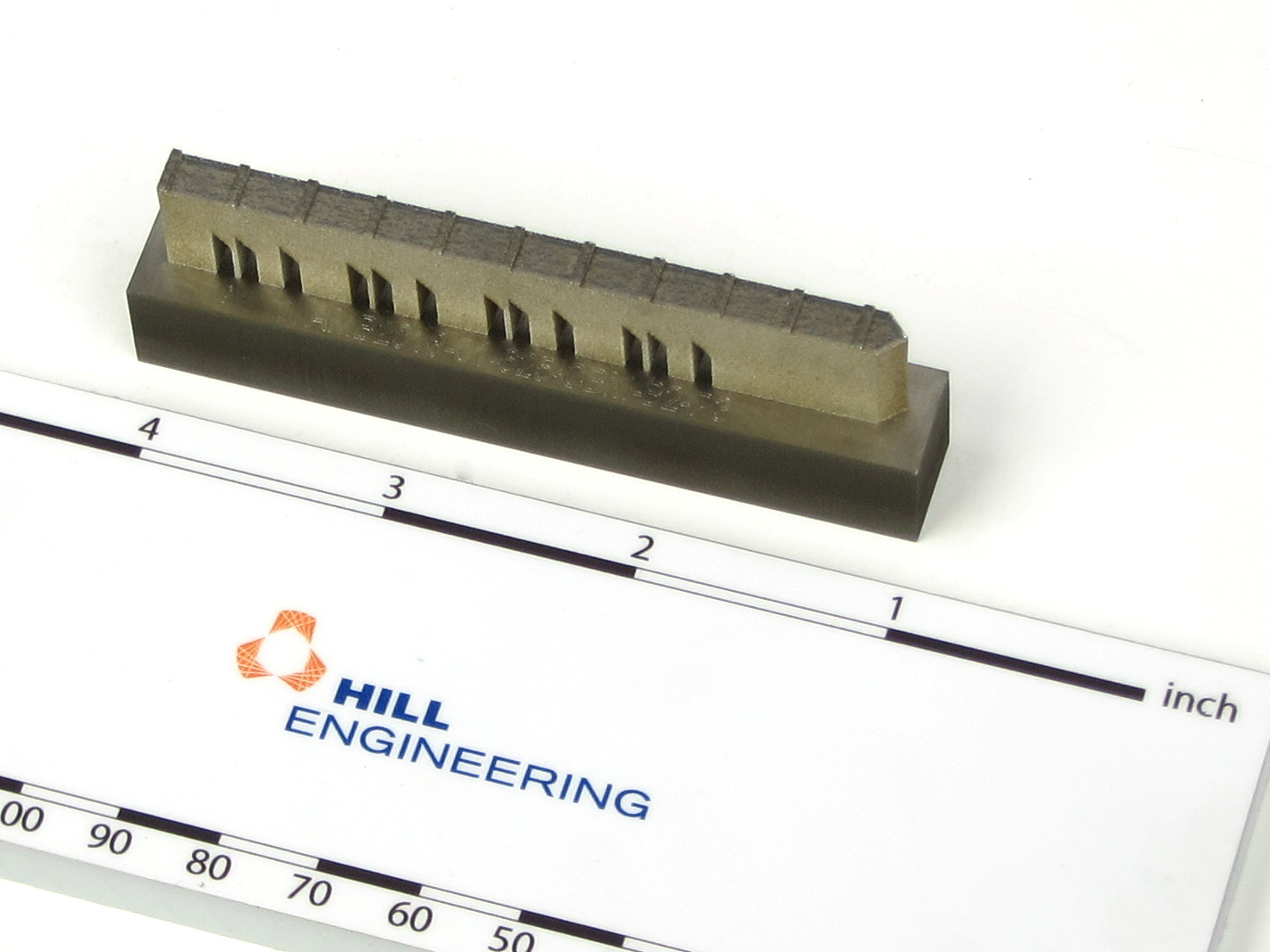

Photograph of AM-Bench residual stress measurement test specimen

Illustration of residual stress measurement results using the contour method