Hill Engineering has recently acquired a new diffractometer and enclosure that will enable us to perform x-ray diffraction (XRD) residual stress measurements in our Rancho Cordova, California, laboratory.

Continue reading Hill Engineering acquires a new XRD system

Category: Residual stress measurement

Search results for Hill Engineering blog posts under the subject category residual stress measurement

New case study: Residual Stress Field Team

We invite you to read our latest case study which highlights the capabilities of our Residual Stress Field Team, who can perform many of our world-class residual stress measurements on-site at a customer’s facility. Continue reading New case study: Residual Stress Field Team

Contour Method Reproducibility Publication

Hill Engineering has participated in a collaborative, interlaboratory effort to quantify contour method residual stress measurement reproducibility. The study, entitled ‘Interlaboratory Reproducibility of Contour Method Data in a High Strength Aluminum Alloy’ was published through Experimental Mechanics, and is provided open access on Springer Link. The background, objective, and methods from the abstract text are as follows:

Continue reading Contour Method Reproducibility PublicationResidual Stress 101: The Hole Drilling Method vlog

The incremental hole drilling method is one of the most common residual stress measurement techniques employed at Hill Engineering. A reliable and rapid process, it’s the subject of our latest Residual Stress 101 episode.

Continue reading Residual Stress 101: The Hole Drilling Method vlogOn the Road with the Residual Stress Field Team

In the ever-evolving landscape of materials science and engineering, on-site solutions are an important component of residual stress testing. That’s why we at Hill Engineering have a dedicated residual stress field team, capable of traveling directly to customers’ locations in order to deliver the same precision and data quality of our in-house residual stress measurements.

Continue reading On the Road with the Residual Stress Field TeamOvercoming Challenges in Residual Stress Measurements on Small Test Specimens Using the Slitting Method

When it comes to measuring residual stress in small test specimens, precision is paramount. The slitting method is well suited to this application due to the high accuracy of wire EDM machining. However, this method is not without its challenges, especially when applied to very small test specimens, such as the 0.022-inch diameter wire we recently measured.

Continue reading Overcoming Challenges in Residual Stress Measurements on Small Test Specimens Using the Slitting MethodPublication alert – Multiscale framework for prediction of residual stress in additively manufactured functionally graded material

Hill Engineering recently published new research with collaborators from around the world including South Korea, Australia, China, and the United Kingdom. The work is titled Multiscale framework for prediction of residual stress in additively manufactured functionally graded material. The abstract text is available here along with a link to the publication.

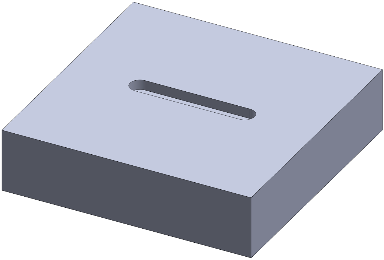

Continue reading Publication alert – Multiscale framework for prediction of residual stress in additively manufactured functionally graded materialNew Case Study – TrueSlot®

Our latest case study is up and it’s all about TrueSlot®, our innovative technique for measuring near-surface residual stress!

Continue reading New Case Study – TrueSlot®Advances in Residual Stress Technology in honor of Drew Nelson

A special Issue of Experimental Mechanics on Advances in Residual Stress Technology in Honor of Drew Nelson was recently published. The Special Issue recognizes Dr. Nelson, Mike’s PhD advisor at Stanford University and a leader in the residual stress community, on becoming emeritus after 40 years of research contributions and teaching on the experimental determination of residual stresses and their effects on fatigue.

Continue reading Advances in Residual Stress Technology in honor of Drew NelsonHill Engineering featured in Railway Track & Structures – August 2022

We recently learned that some hole drilling method and contour method results were highlighted in the August 2022 issue of Railway Track and Structures. The article is titled Residual stress investigation of ultrasonic impact treated and untreated thermite welds.

Continue reading Hill Engineering featured in Railway Track & Structures – August 2022