Hill Engineering has recently acquired the state-of-the-art JPT MOPA M7 Laser Engraver with a 175x175mm lens and an 80mm Rotary Axis. This strategic investment will improve our laboratory capabilities, enabling us to deliver unparalleled results to our clients!

Continue reading Hill Engineering Acquires New SFX Laser EngraverCategory: Our Work

Search results for Hill Engineering blog posts under the subject category our work

New publication: Effects of high‑energy laser peening followed by pre‑hot corrosion on stress relaxation, microhardness, and fatigue life and strength of single‑crystal nickel CMSX‑4® superalloy

Hill Engineering recently published new collaborative research in the International Journal of Advanced Manufacturing Technology titled Effects of high‑energy laser peening followed by pre‑hot corrosion on stress relaxation, microhardness, and fatigue life and strength of single‑crystal nickel CMSX‑4® superalloy and appears in International Journal of Advanced Manufacturing Technology. The abstract text is available here along with a link to the publication.

Continue reading New publication: Effects of high‑energy laser peening followed by pre‑hot corrosion on stress relaxation, microhardness, and fatigue life and strength of single‑crystal nickel CMSX‑4® superalloyPresentations at TMS 2023 Annual Meeting & Exhibition!

Hill Engineering recently co-authored presentations at the TMS 2023 Annual Meeting & Exhibition in San Diego, CA on March 19th through the 23rd. The TMS Annual Meeting & Exhibition brings together more than 4,000 engineers, scientists, business leaders, and other professionals in the minerals, metals, and materials fields for a comprehensive, cross-disciplinary exchange of technical knowledge. The abstracts for the presentations that we co-authored are copied below.

Continue reading Presentations at TMS 2023 Annual Meeting & Exhibition!New Vlog: How To Apply A Strain Gage

Strain gages feature in a large portion of the residual stress measurements we perform at Hill Engineering, which is why we pride ourselves on our ability to correctly choose and apply strain gages to fit any measurement needs.

Continue reading New Vlog: How To Apply A Strain GageHill Engineering’s DART issued second US patent!

Hill Engineering has been recently issued its second US patent for the DART™ measurement system. This updated device offers improved residual stress measurements within small-diameter pipe applications, allowing for more accurate analysis in both in-laboratory and non-laboratory settings.

Continue reading Hill Engineering’s DART issued second US patent!New Case Study – TrueSlot®

Our latest case study is up and it’s all about TrueSlot®, our innovative technique for measuring near-surface residual stress!

Continue reading New Case Study – TrueSlot®Hill Engineering issued first Japanese patent for the DART!

Hill Engineering is officially going global!

We are proud to announce we’ve been issued our first Japanese patent for the DART™, our Device for Automated Residual stress Testing.

Continue reading Hill Engineering issued first Japanese patent for the DART!TrueSlot® – near surface residual stress measurement

TrueSlot® is an innovative technique for measuring near-surface residual stress that is more reliable than conventional techniques.

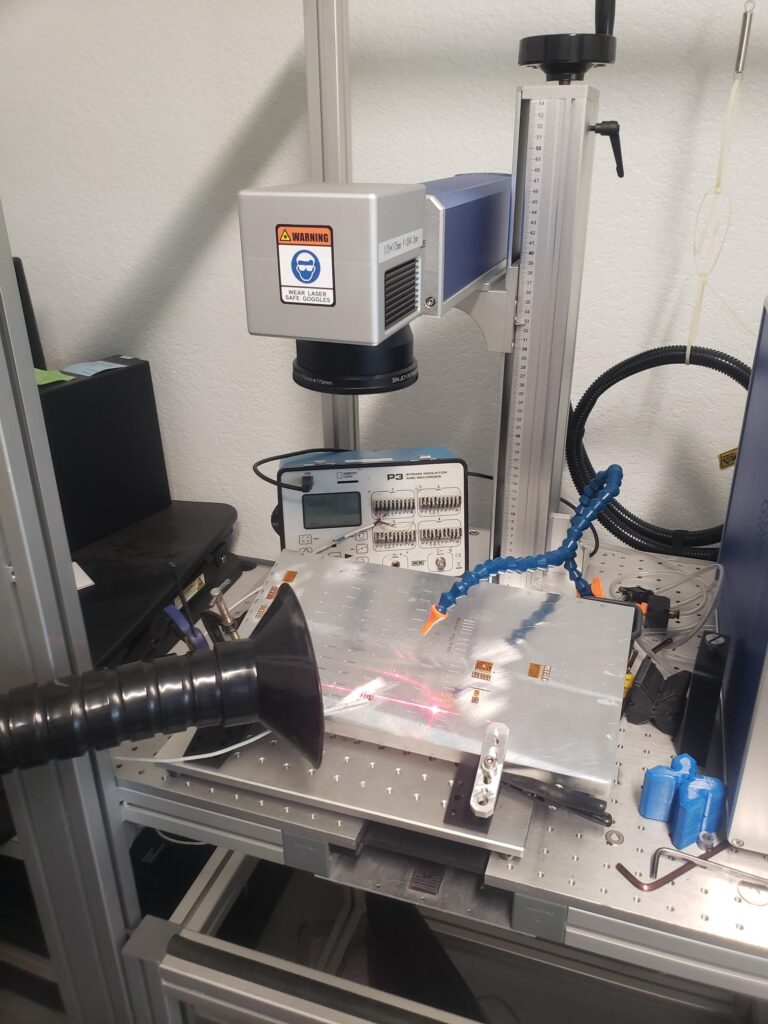

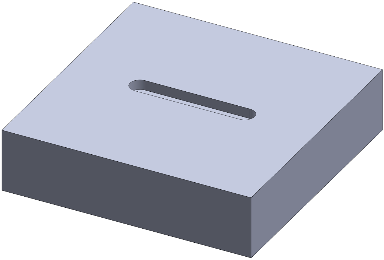

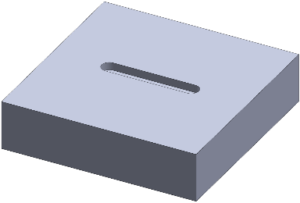

TrueSlot® is a residual stress measurement technique for generating a profile of residual stress versus depth from the material surface. The stress computation is similar to slitting but offers more sensitivity near the surface due to the proximity of the strain gage.

Additionally, TrueSlot® is globally less invasive than slitting because the volume of removed material is localized to the surface and does not typically extend through most of the specimen thickness.

The physical application of TrueSlot® is like hole drilling, however instead of a shallow hole being milled into the body of a specimen containing residual stress, the material removed is a shallow slot. The strain released with each incremental slot depth is measured near the slot using a strain gage.

TrueSlot® is useful for

- Production quality control applications

- Applications requiring in-field measurements with portable equipment

- Near-surface residual stress determination

- Parts with large or complex geometry

- Applications with challenging measurement access

- Applications requiring rapid turn time

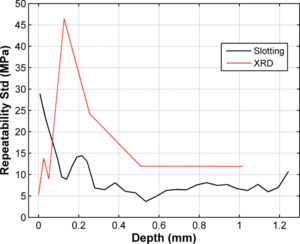

TrueSlot® was found to have better repeatability when compared with conventional x-ray diffraction.

You can read about our repeatability study here.

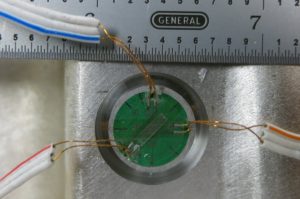

TrueSlot® measurements are performed using our DARTTM system for automated residual stress measurement.

New Case Study: Express RS

Our latest case study highlights ExpressRS®, our dedicated service to high-priority, accelerated schedule projects.

Continue reading New Case Study: Express RSExpressRS® – expedited residual stress results

Are you working on a project with a tight deadline? We’re here to help!

Hill Engineering offers expedited residual stress measurement services (ExpressRS®). With ExpressRS®, our customers can expect the same level of high-quality residual stress measurement results within an accelerated delivery time – typically less than 1 week for most jobs and next day service is available in select cases. When our customers choose ExpressRS®, their project is given priority in our measurement laboratory queue to help meet tighter deadlines without sacrificing quality.

Hill Engineering is a global leader in residual stress measurements. We believe every materials engineer, designer, and manager should have solid data upon which they can make sound decisions. Our broad range of best-in-class measurement capabilities ensures that we can tailor our approach to your specific project needs.

The following residual stress measurement techniques are available through ExpressRS®:

Hill Engineering has the expertise to address issues arising in materials, manufacturing, and design engineering, with unique capabilities in residual stress measurement, material testing, service life assessment, and mechanical design. Our laboratory maintains an active ISO 17025 accreditation.

ExpressRS® gives our customers access to this expertise with urgency. If you have any questions or are interested in utilizing our rapid-results service, please contact us for more information.