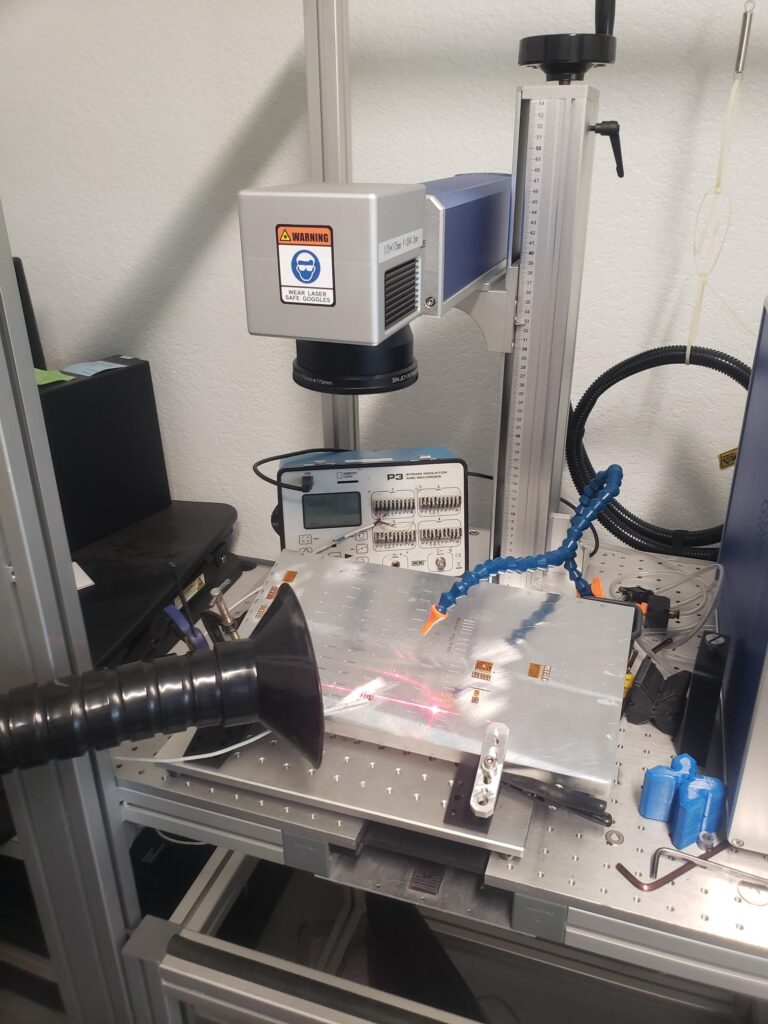

Hill Engineering has recently acquired the state-of-the-art JPT MOPA M7 Laser Engraver with a 175x175mm lens and an 80mm Rotary Axis. This strategic investment will improve our laboratory capabilities, enabling us to deliver unparalleled results to our clients!

The JPT MOPA M7 Laser Engraver offers a wide range of application advantages that make it an exciting addition to Hill Engineering’s laboratory. The 60W power output ensures remarkable precision and control during the engraving process. This level of power enables the engraver to produce intricate designs on a variety of materials, aluminum, stainless steel (including color markings), plastics, and more.

Additionally, the 175x175mm lens further enhances the precision of the engraving, allowing for intricate detailing and fine line work, which is beneficial for industries such as metal surface processing, peeling coating, semi-conductor manufacturing, and electronics.

The JPT MOPA M7 Laser Engraver boasts impressive technical specifications that contribute to its superior performance. The engraver operates on a highly efficient MOPA fiber laser source, which ensures excellent beam quality, stability, and reliability.

The large engraving area provides ample space for creating detailed designs on various materials.

Hill Engineering’s acquisition of the JPT MOPA M7 Laser Engraver marks an exciting milestone in our quest for excellence in precision engineering!

For more information about our laser engraving capabilities or any of the residual stress measurement services we offer, please contact us.