Are you working on a project with a tight deadline? We’re here to help!

Hill Engineering offers expedited residual stress measurement services (ExpressRS®). With ExpressRS®, our customers can expect the same level of high-quality residual stress measurement results within an accelerated delivery time – typically less than 1 week for most jobs and next day service is available in select cases. When our customers choose ExpressRS®, their project is given priority in our measurement laboratory queue to help meet tighter deadlines without sacrificing quality.

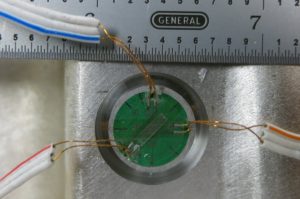

Hill Engineering is a global leader in residual stress measurements. We believe every materials engineer, designer, and manager should have solid data upon which they can make sound decisions. Our broad range of best-in-class measurement capabilities ensures that we can tailor our approach to your specific project needs.

The following residual stress measurement techniques are available through ExpressRS®:

Hill Engineering has the expertise to address issues arising in materials, manufacturing, and design engineering, with unique capabilities in residual stress measurement, material testing, service life assessment, and mechanical design. Our laboratory maintains an active ISO 17025 accreditation.

ExpressRS® gives our customers access to this expertise with urgency. If you have any questions or are interested in utilizing our rapid-results service, please contact us for more information.