Hill Engineering recently published new collaborative research in the International Journal of Advanced Manufacturing Technology titled Effects of high‑energy laser peening followed by pre‑hot corrosion on stress relaxation, microhardness, and fatigue life and strength of single‑crystal nickel CMSX‑4® superalloy and appears in International Journal of Advanced Manufacturing Technology. The abstract text is available here along with a link to the publication.

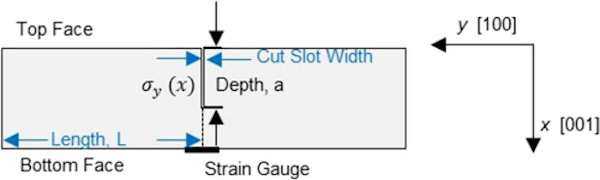

This study investigated the stress relaxation and fatigue life and strength of laser-peened single-crystal nickel superalloy specimens compared to unpeened and shot-peened specimens following hot corrosion exposure and then fatigue testing. The specimens were treated by conventional laser peening and a new cyclic laser peening plus thermal microstructure engineering process. The latter treatment supports the benefit of a unique process involving application of layers of laser peening using high energy with large footprint spots combined with interspersed cyclic annealing. Stress measurements by slitting showed the plastic penetration depth of laser peening exceeded shot peening by a factor of 24. Unpeened and peened specimens were exposed to sulphate corrosives at 700 °C for 300 h and then fatigue tested. Tests of five non-laser-peened specimens all failed in low-cycle fatigue regime, whereas three identically tested laser-peened specimens all achieved multi-million-cycle runout without failure, indicating fully consistent large benefit for life by laser peening. Additional tests also showed fatigue strength improvement of 2:1 by laser peening. Residual stress measurements post hot-corrosion exposure and fatigue testing showed notable 5 mm depth retention of residual eigenstress in a laser-peened specimen.

If you are interested, the full publication is available here.