The incremental hole drilling method is one of the most common residual stress measurement techniques employed at Hill Engineering. A reliable and rapid process, it’s the subject of our latest Residual Stress 101 episode.

Continue reading Residual Stress 101: The Hole Drilling Method vlogTag: DART

On the Road with the Residual Stress Field Team

In the ever-evolving landscape of materials science and engineering, on-site solutions are an important component of residual stress testing. That’s why we at Hill Engineering have a dedicated residual stress field team, capable of traveling directly to customers’ locations in order to deliver the same precision and data quality of our in-house residual stress measurements.

Continue reading On the Road with the Residual Stress Field TeamHill Engineering’s DART issued second US patent!

Hill Engineering has been recently issued its second US patent for the DART™ measurement system. This updated device offers improved residual stress measurements within small-diameter pipe applications, allowing for more accurate analysis in both in-laboratory and non-laboratory settings.

Continue reading Hill Engineering’s DART issued second US patent!Hill Engineering issued first Japanese patent for the DART!

Hill Engineering is officially going global!

We are proud to announce we’ve been issued our first Japanese patent for the DART™, our Device for Automated Residual stress Testing.

Continue reading Hill Engineering issued first Japanese patent for the DART!TrueSlot® – near surface residual stress measurement

TrueSlot® is an innovative technique for measuring near-surface residual stress that is more reliable than conventional techniques.

TrueSlot® is a residual stress measurement technique for generating a profile of residual stress versus depth from the material surface. The stress computation is similar to slitting but offers more sensitivity near the surface due to the proximity of the strain gage.

Additionally, TrueSlot® is globally less invasive than slitting because the volume of removed material is localized to the surface and does not typically extend through most of the specimen thickness.

The physical application of TrueSlot® is like hole drilling, however instead of a shallow hole being milled into the body of a specimen containing residual stress, the material removed is a shallow slot. The strain released with each incremental slot depth is measured near the slot using a strain gage.

TrueSlot® is useful for

- Production quality control applications

- Applications requiring in-field measurements with portable equipment

- Near-surface residual stress determination

- Parts with large or complex geometry

- Applications with challenging measurement access

- Applications requiring rapid turn time

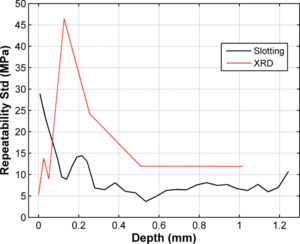

TrueSlot® was found to have better repeatability when compared with conventional x-ray diffraction.

You can read about our repeatability study here.

TrueSlot® measurements are performed using our DARTTM system for automated residual stress measurement.

Pipe Corrosion Inspection: Hill Engineering in the field

Eric Summer and I recently packed up the DART repair tool for a trip down to Naval Base Ventura County in Port Hueneme, CA. There, we participated in the Navy’s Repair Technology Exercise, or REPTX 2022. Onboard the Navy’s Self Defense Test Ship (SDTS), Hill Engineering demonstrated how the DART repair tool can be applied as an industrial maintenance solution.

Continue reading Pipe Corrosion Inspection: Hill Engineering in the field