Strain gages feature in a large portion of the residual stress measurements we perform at Hill Engineering, which is why we pride ourselves on our ability to correctly choose and apply strain gages to fit any measurement needs.

Continue reading New Vlog: How To Apply A Strain GageAuthor: Robert Pires

Hill Engineering’s DART issued second US patent!

Hill Engineering has been recently issued its second US patent for the DART™ measurement system. This updated device offers improved residual stress measurements within small-diameter pipe applications, allowing for more accurate analysis in both in-laboratory and non-laboratory settings.

Continue reading Hill Engineering’s DART issued second US patent!New Case Study – TrueSlot®

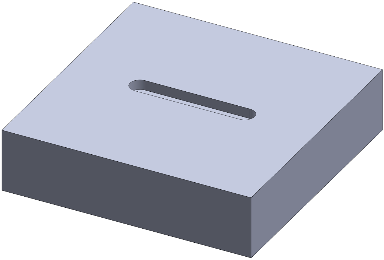

Our latest case study is up and it’s all about TrueSlot®, our innovative technique for measuring near-surface residual stress!

Continue reading New Case Study – TrueSlot®Hill Engineering issued first Japanese patent for the DART!

Hill Engineering is officially going global!

We are proud to announce we’ve been issued our first Japanese patent for the DART™, our Device for Automated Residual stress Testing.

Continue reading Hill Engineering issued first Japanese patent for the DART!The Big 200! – Celebrating a milestone blog post

Gather round readers!

We are very excited today because in this blog we cross an incredible milestone: our 200th post! That’s right. Since the inception of the Hill Engineering blog back in March 2016, we have published 200 times.

Let’s take a look back over the past 7 years of blogging bliss!

Continue reading The Big 200! – Celebrating a milestone blog postNew Case Study: Express RS

Our latest case study highlights ExpressRS®, our dedicated service to high-priority, accelerated schedule projects.

Continue reading New Case Study: Express RSNew case study: Residual Stress

The heart of work at Hill Engineering has everything to do with residual stress. That’s why we thought it was about time we published a case study giving a general overview of what residual stress is, and why it is so important for designers and manufacturers to consider.

Continue reading New case study: Residual StressBAMpF achieves USAF software certification

We are happy to announce that our BAMpF® software version 8.x has achieved software certification from the United States Airforce (USAF) to operate on the USAF network.

Continue reading BAMpF achieves USAF software certificationHE Pet Spotlight – Sunshine and Malibu

When we’re not performing residual stress measurements, some of the Hill Engineering team members love spending time with their furry friends! This is true for Debra LaChappell who lives with her golden retriever lab mix Sunshine, and her cat, Malibu!

Continue reading HE Pet Spotlight – Sunshine and MalibuPresentation: 1st ASTM Bearing and Transmission Steels Technology Symposium

Hill Engineering will be presenting at the upcoming 1st ASTM Bearing and Transmission Steels Technology Symposium in New Orleans, LA on November 2nd through the 16th. We invite you to come see us.

Held at the Sheraton New Orleans Hotel, the objective of the symposium is to bring together rolling bearing and transmission steel practitioners from the steel industries, rolling bearing and transmission product producers, research and development institutes and academia, to present the latest steel technologies and developments.

The abstract for Hill Engineering’s presentation, titled Efficient Residual Stress Quantification in M50NiL Bearing Steel, is included below.

Continue reading Presentation: 1st ASTM Bearing and Transmission Steels Technology Symposium