| Hill Engineering is presenting at the upcoming Propulsion Safety & Sustainment Conference (PS&S) in Washington, D.C. from April 23rd through April 25th. We invite you to come see us. The mission of this conference is to proactively address or prevent problems with safety, readiness, reliability, and sustainment within the tri-service turbine engine fleet. This is to be accomplished through the transition of existing and emerging technologies. Hill Engineering’s presentation will include a summary of recent work related to residual stress measurement in support of production quality control. The abstract text is presented below. Aircraft engine and structural components are being produced from forgings with increasingly complex geometries in a wide range of aerospace alloys. The forging process involves a number of steps required to attain favorable material properties (e.g., heat treatment, rapid quench, cold work stress relieving, and artificial aging). These processing steps, however, also result in the introduction of residual stress. Excessive bulk residual stresses can have negative consequences including: part distortion during machining and/or during service, reduced crack initiation life, increased crack growth rates, and an overall reduction in part life. This presentation will describe an approach for quality management of residual stresses in aerospace forgings. The quality management system relies upon computational process modeling, residual stress measurement, and the integration of these concepts within the framework of a standard production quality system. If you are planning to attend the conference, please stop by to discuss Hill Engineering’s capabilities in fatigue analysis and design and residual stress measurement. Please contact us for more information. |

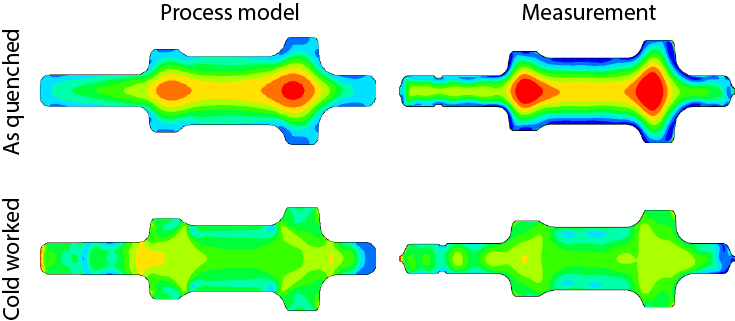

Illustration of residual stress in an aluminum forging before and after cold work residual stress relief