As a follow-up to our previous post about additive manufacturing (AM) we wanted to highlight some other activities in the additive manufacturing space.

One such activity that Hill Engineering has been involved in is the NIST AM-Bench program. AM-Bench is developing a continuing series of controlled benchmark tests with two initial goals: 1) to allow modelers to test their simulations against rigorous, highly controlled additive manufacturing benchmark test data, and 2) to encourage additive manufacturing practitioners to develop novel mitigation strategies for challenging build scenarios. As part of this program, Hill Engineering has been working in collaboration with UC Davis to support residual stress measurement activities using the contour method.

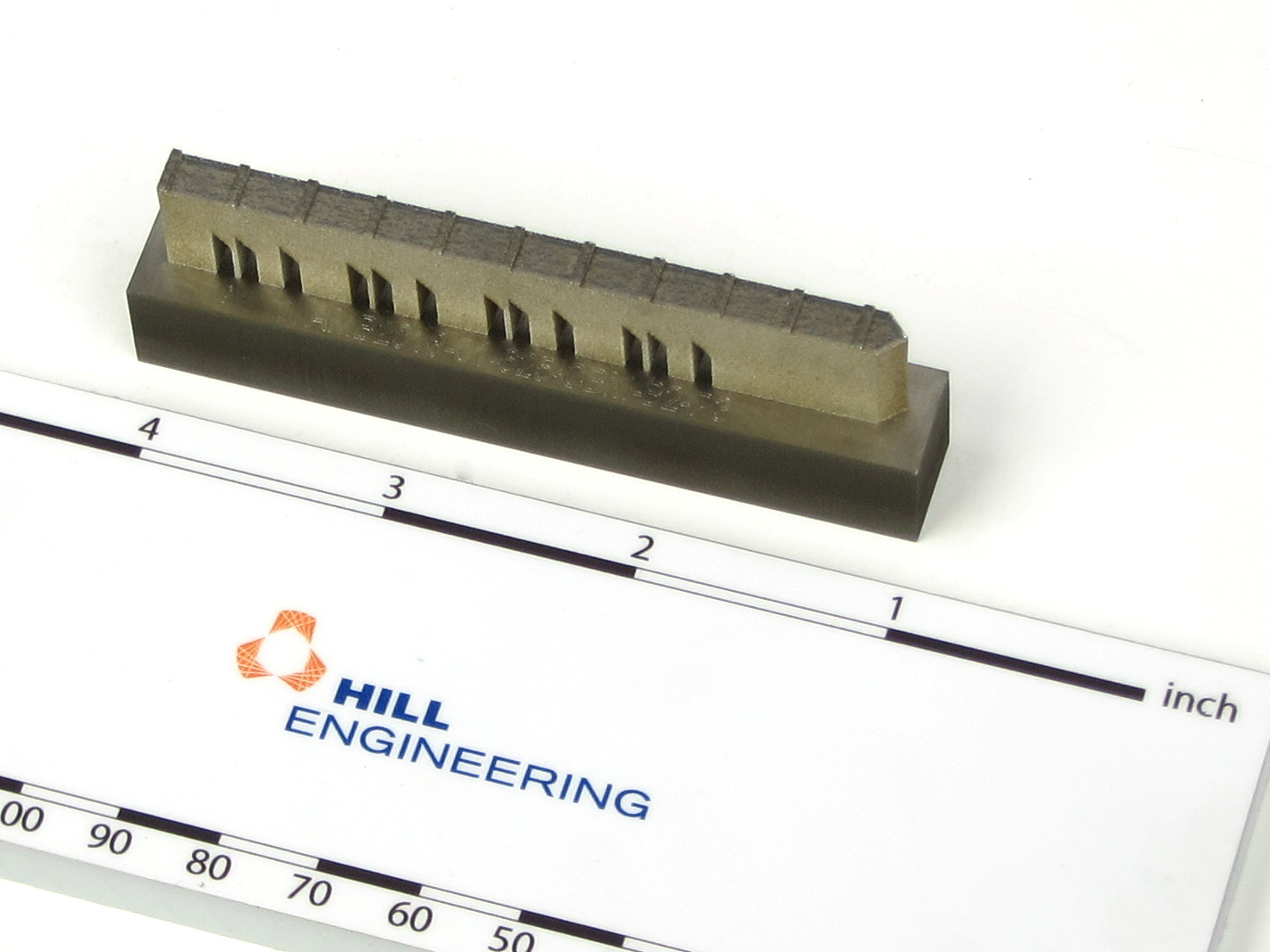

One recent AM-Bench activity involves laser powder bed fusion (LPBF) 3D builds of nickel-based superalloy IN625. The bridge shape specimen is shown in the figure below. The AM-Bench organization collected results from a variety of tests including: part deflection, microstructure, phase transformations, and residual stress.

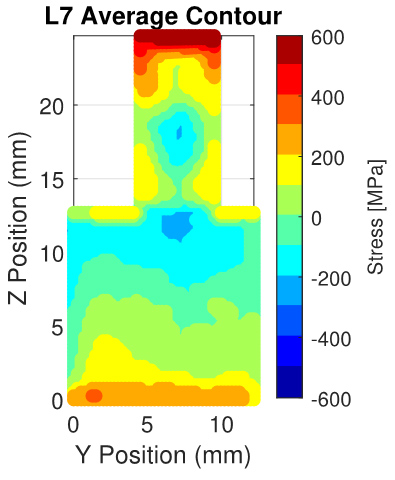

A 2D map of the residual stress measured in the additive manufacturing test specimen using the contour method is shown below. Additional information about the AM-Bench program and other test results are available on the NIST website.

Please contact us for additional information.

Photograph of AM-Bench residual stress measurement test specimen

Illustration of residual stress measurement results using the contour method