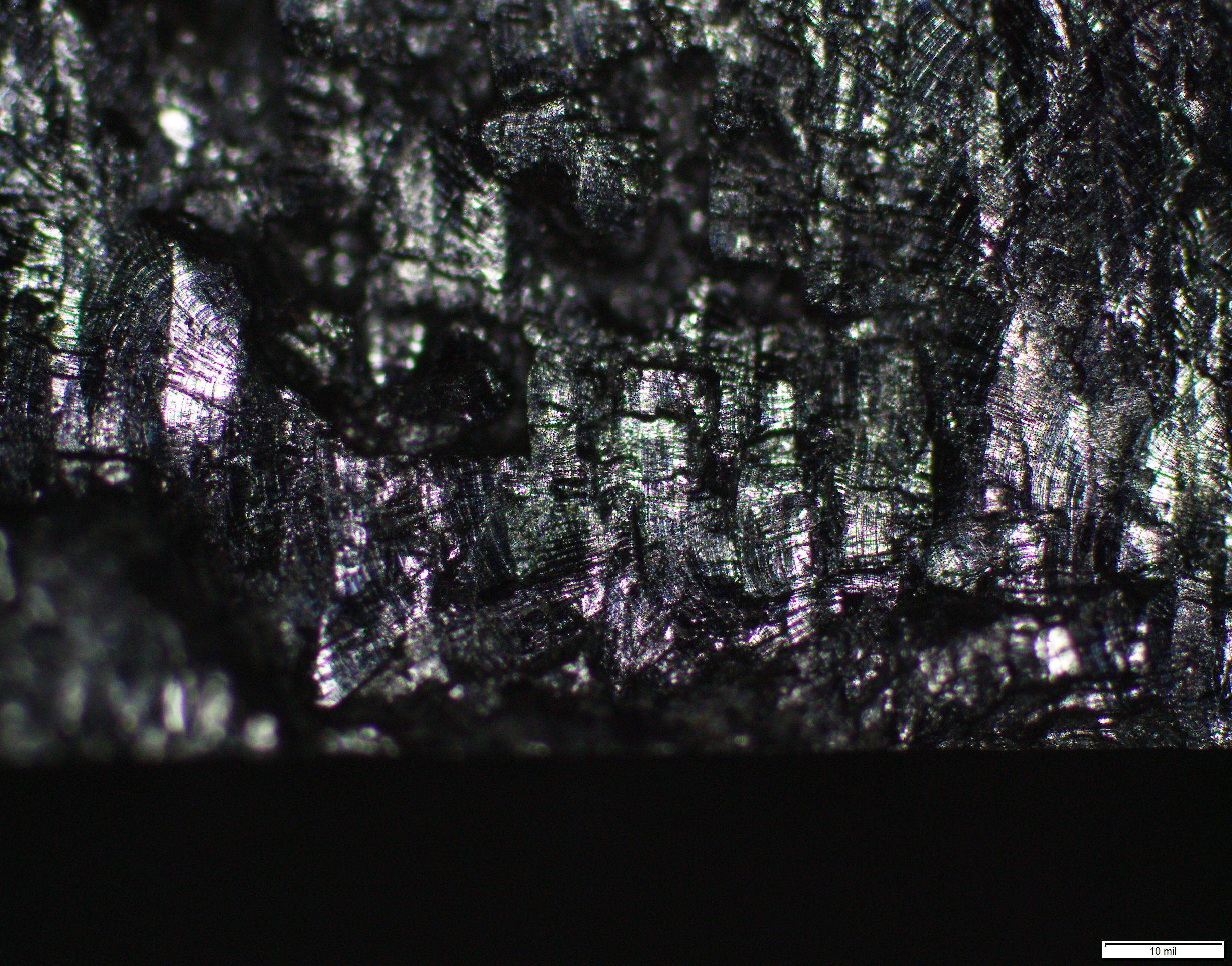

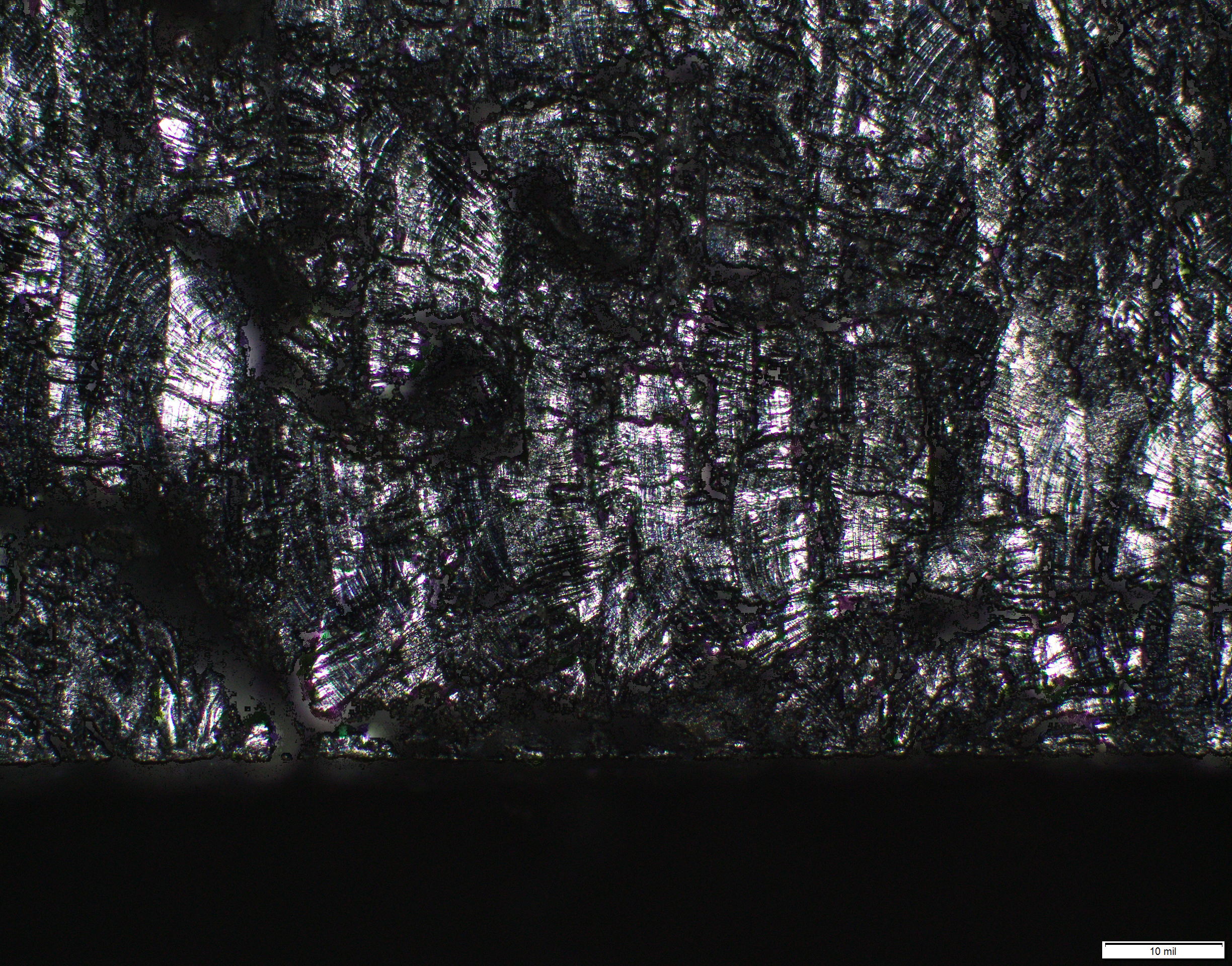

We’ve previously talked about fracture surfaces created as a result of material fatigue. Through fatigue tests, we are able to create a typical loading cycle on a test specimen to see how the number and magnitude of cycles affects the growth of cracks on the surface. After the test, we can perform fatigue analysis to see how the crack grew over time using a microscope.

At Hill Engineering, we use a measuring microscope for small- and large-scale measurements. Performing a failure analysis on a fracture surface is just one of the uses of our measuring microscope. We also use the microscope to check machined parts for accuracy and perform post-inspection measurements of laboratory specimens. An interesting feature of our microscope is its ability to capture a fully focused image so the operator can view every feature of the specimen without having to adjust the focus. With this, we are able to more easily identify the fatigue cracks on the surface. Take a look at some images taken with our measuring microscope below and see what a difference having the ability to fully focus an image makes.

For more information about fatigue analysis or fatigue tests, please contact us.

Image of a fracture surface with fatigue cracking

Fully focused image of a fracture surface with fatigue cracking