Additive manufacturing (AM) is a manufacturing process that deposits material in a controlled manner to build three-dimensional part geometry (bit by bit). This is in contrast to traditional manufacturing processes where material is cut or removed (i.e., subtracted) from the raw stock to create the intended part shape. The potential for additive manufacturing to significantly improve the economics and performance of manufactured parts for certain applications has made it a popular topic. However, since most additive manufacturing processes are highly thermal (e.g., material is deposited in a melted form and solidifies into the desired shape) significant residual stresses can develop. Hill Engineering has been working with many collaborators to better understand the influence of these processes on residual stress.

Selective laser melting (SLM) is a popular AM process utilized in a wide variety of applications. SLM produces large thermal gradients and fast cooling rates. This produces high levels of residual stress, which can result in cracking and distortion of the final part. Recently, Hill Engineering worked with the Air Force Research Laboratory to understand the influence of SLM process parameters on the resulting residual stress in Ti-6Al-4V specimens.

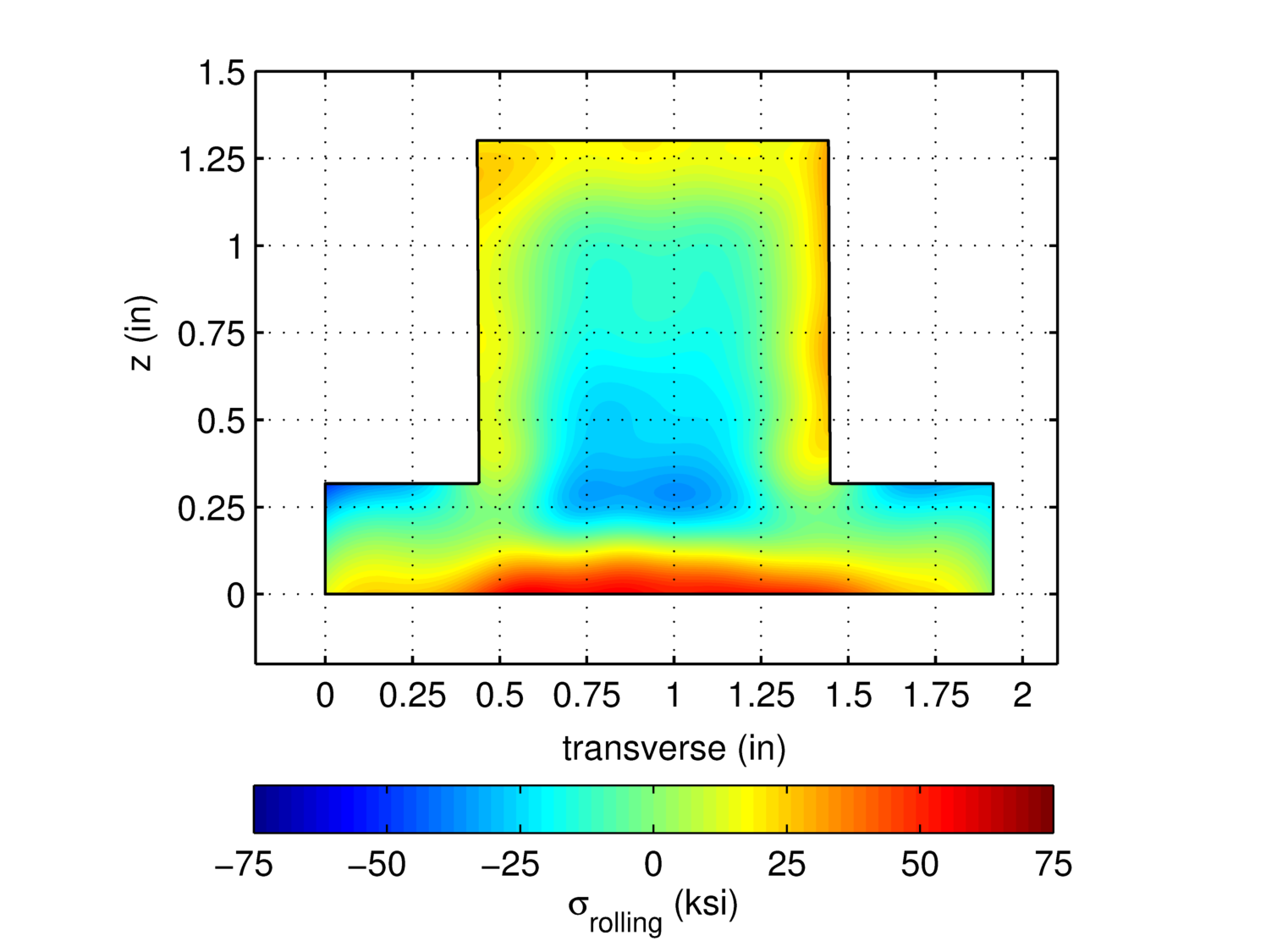

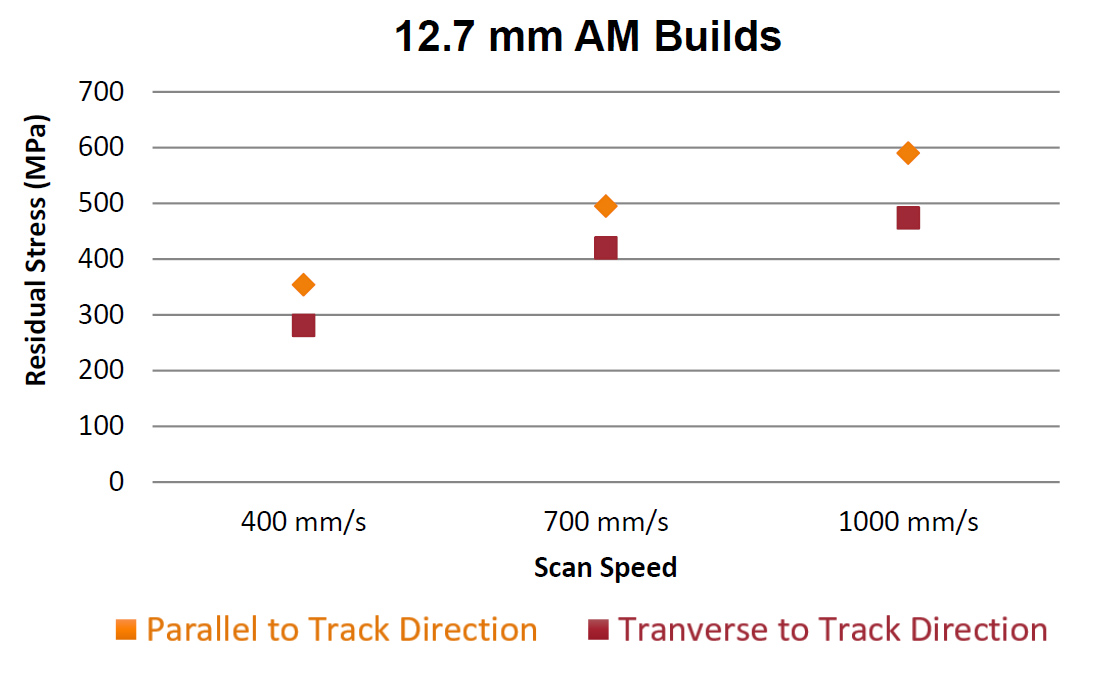

As part of this program AFRL produced test specimens that consisted of 1 inch by 1 inch builds (of various heights) on 3 inch by 3 inch substrates. These specimens were produced using different process parameters (scan speed, laser power, and build height). Hill Engineering performed residual stress measurements using hole drilling and the contour method to quantify the relationship between additive manufacturing process parameters and residual stress. Example results are shown in the figures below. The full results will be available in a future publication.

We’ll highlight some additional applications of residual stress in additive manufacturing in future blog posts and case studies on our website, so please check back for updates (or subscribe to our mailing list or social media accounts on the main page). In the meantime, please contact us for more information.

Illustration of residual stress in an additive manufactured Ti-6Al-4V specimen measured using the contour method

Increasing the laser scan speed tends to increase the residual stress for additive manufactured Ti-6Al-4V specimens [ref: Levkulich, TMS 2017]