In 2019 Hill Engineering licensed VEQTER Ltd.’s world-leading Deep-Hole Drilling (DHD) technology. Under this agreement, Hill Engineering is delivering state-of-the-art DHD measurements within the North and South American Continents. Results from a recent DHD measurement on a bent-beam specimen are shared in this blog post.

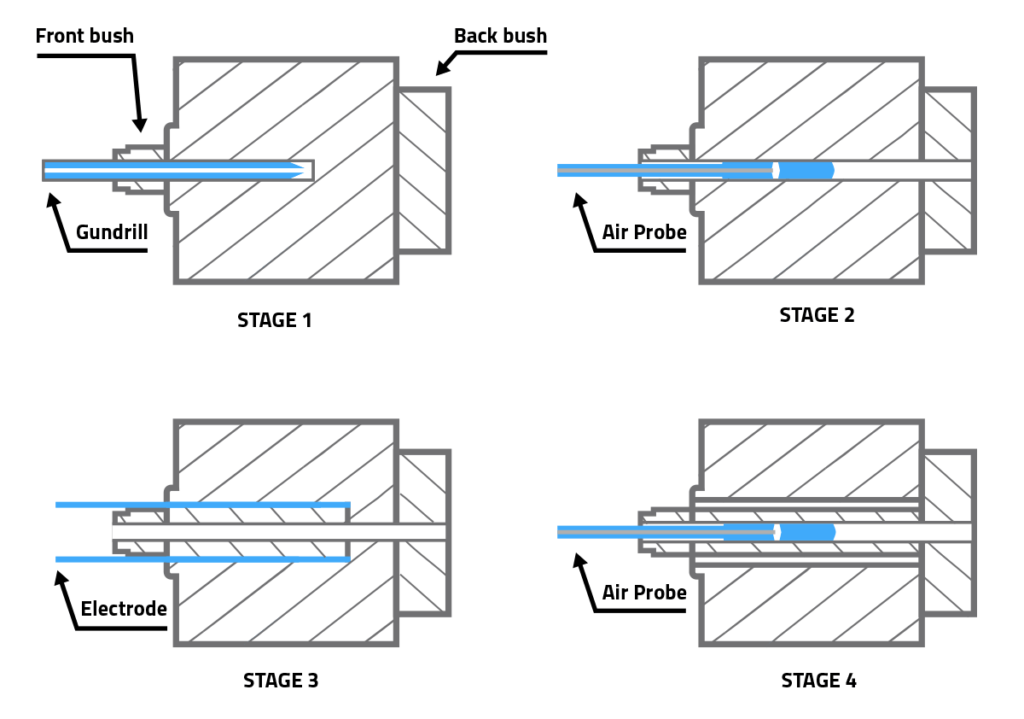

The Deep-Hole Drilling technique involves drilling a reference hole through the component and accurately measuring its diameter before and after residual stress release by trepanning coaxially around it. The measured deformation of the reference hole (before and after residual stress release) enables the original residual stresses to be calculated using elasticity theory.

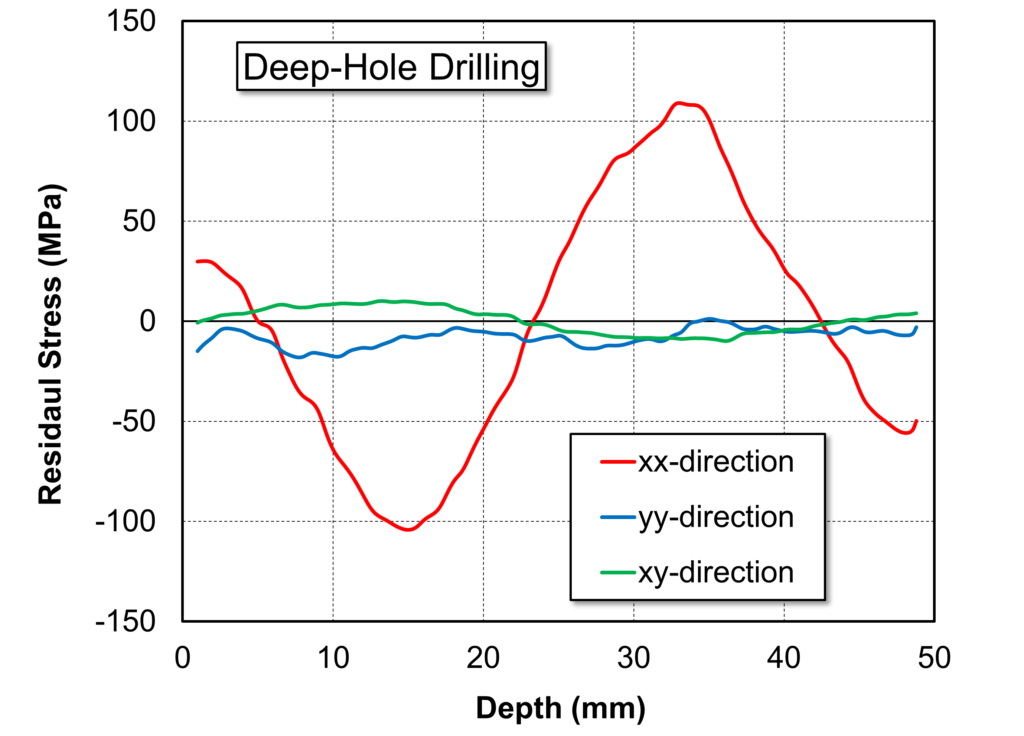

Hill Engineering recently performed a Deep-Hole Drilling measurement on a beam, which had residual stresses imparted in it by a four-point bending rig. Applying four-point bending to a beam induces a repeatable residual stress field, making this ‘bent-beam’ specimen an ideal candidate for a test measurement. A plot of the measured residual stress in the specimen is shown below. The x-direction corresponds with the long axis of the specimen. This is the direction that is loaded during bending and therefore this is the direction with the highest magnitude residual stress.

If you have further questions about deep hole drilling or any of the other residual stress measurement techniques we offer, please contact us for more information.