As we discuss in a related case study, aluminum alloy heat treatment is a three-step process designed to achieve the desired properties. The process involves: 1) solution heat treatment (SHT) at an elevated temperature below the melting point, 2) quenching in a tank of fluid (e.g., 140-180°F water), and 3) age hardening. While providing good properties, the heat treatment has the negative side effect of creating bulk residual stress and distortion. One approach to mitigate this problem is the application of a post-heat treatment mechanical stress relief process.

Our latest case study highlights Hill Engineering’s mechanical stress relief process simulation capabilities and how they can be utilized to reduce uncertainty in planning and improve processes through validated models. The case study focuses on modeling of mechanical stress relief processes for representative aluminum forgings and extrusions.

Click the link above to read the full write-up, or visit our case study page to read through any of our previous work highlights. If you have further questions, don’t hesitate to contact us for more information.

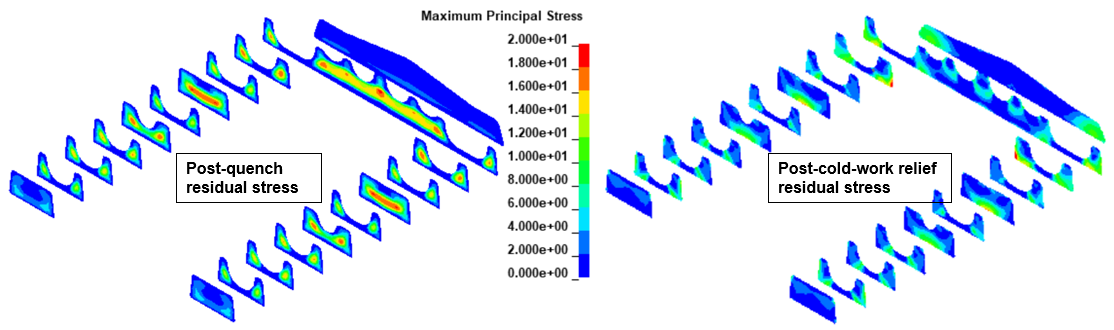

Predicted residual stress post-quench (left) and post-cold-work-stress-relief (right) for an example aluminum forging