Hill Engineering recently published new research outlining a approach for predicting fatigue crack growth in the presence of residual stress fields. The paper is titled Measurement-driven, model-based estimation of residual stress and its effect on fatigue crack growth. Part 2: fatigue crack growth testing and modeling and appears in International Journal of Fatigue. The abstract text is available here along with a link to the publication.

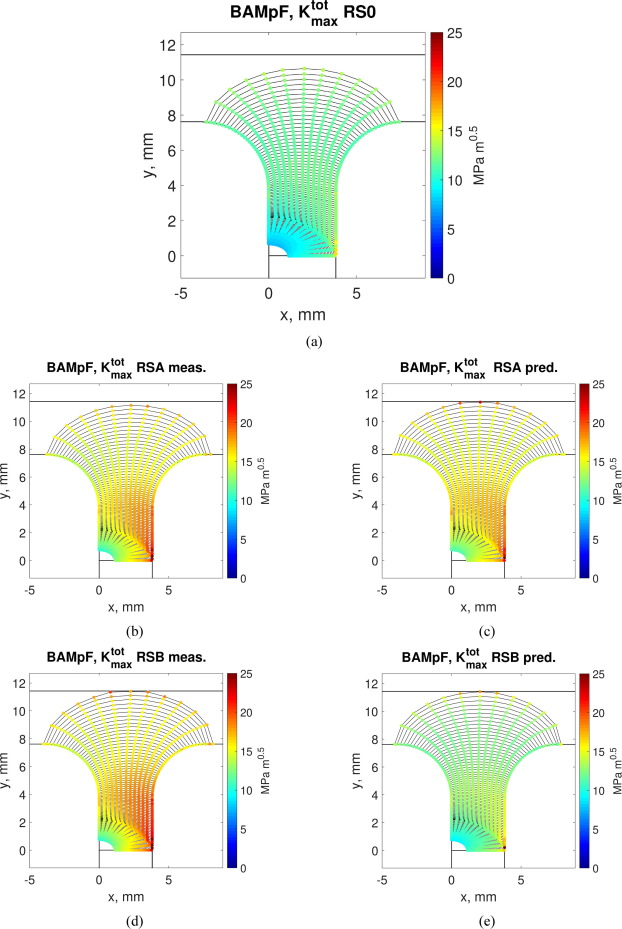

This paper assesses the accuracy of fatigue crack growth (FCG) predictions for high-strength aluminum samples containing residual stress (RS) and complex two-dimensional cracks subjected to constant amplitude load. FCG predictions use linear-elastic, multi-point fracture mechanics. A first prediction includes RS estimated by the model described in Part 1; a second prediction includes RS measured by the contour method. FCG test data show a significant influence of RS. Ignoring the RS results in a +60% error in predicted FCG life (non-conservative). Including RS improves predictions of crack growth significantly (errors better than +26% (estimated RS) and -14% (measured RS)).

If you are interested, the full publication is available here.