A new Hill Engineering article titled “Near Edge Residual Stress Measurement Using Incremental Hole Drilling” has been published online in Experimental Mechanics. This study examines the effects of performing a hole drilling residual stress measurement near the free edge of a specimen. Below is the abstract text.

Author: Robert Pires

Meet Josh’s Adventure-Ready Llamas: Bowie, Tito, and Boomer

If you’ve ever dreamed of embarking on a backcountry camping trip with some unique companions, then you’ll be inspired by Hill Engineering’s Josh Hodges and his three adventure buddies – Bowie, Tito, and Boomer.

Continue reading Meet Josh’s Adventure-Ready Llamas: Bowie, Tito, and Boomer

Enhancing Efficiency: Hill Engineering’s scanning profilometer system

In the intricate world of residual stress analysis, the pursuit of precision is an ongoing endeavor. The Hill Engineering Scanning Profilometer (HESP) was a result of this perennial struggle, offering a satisfying, in-house solution that revolutionized our ability to perform contour method residual stress measurements.

Continue reading Enhancing Efficiency: Hill Engineering’s scanning profilometer systemContour Method Reproducibility Publication

Hill Engineering has participated in a collaborative, interlaboratory effort to quantify contour method residual stress measurement reproducibility. The study, entitled ‘Interlaboratory Reproducibility of Contour Method Data in a High Strength Aluminum Alloy’ was published through Experimental Mechanics, and is provided open access on Springer Link. The background, objective, and methods from the abstract text are as follows:

Continue reading Contour Method Reproducibility PublicationHill Engineering Aims For The Horizon With Expansion

Hill Engineering is ringing in 2024 with a new expansion. By incorporating a neighboring suite into our office design, Hill Engineering now occupies our entire building, positioning us for greater achievements in the future.

Continue reading Hill Engineering Aims For The Horizon With ExpansionResidual Stress 101: The Hole Drilling Method vlog

The incremental hole drilling method is one of the most common residual stress measurement techniques employed at Hill Engineering. A reliable and rapid process, it’s the subject of our latest Residual Stress 101 episode.

Continue reading Residual Stress 101: The Hole Drilling Method vlogOn the Road with the Residual Stress Field Team

In the ever-evolving landscape of materials science and engineering, on-site solutions are an important component of residual stress testing. That’s why we at Hill Engineering have a dedicated residual stress field team, capable of traveling directly to customers’ locations in order to deliver the same precision and data quality of our in-house residual stress measurements.

Continue reading On the Road with the Residual Stress Field TeamHill Engineering Joins CMTC’s Made in California Program: A New Chapter in Manufacturing Excellence

In an exciting development for both the aerospace industry and the state of California, Hill Engineering has officially been welcomed to the California Manufacturing Technology Consulting (CMTC) Made in California Program.

Continue reading Hill Engineering Joins CMTC’s Made in California Program: A New Chapter in Manufacturing ExcellenceWe never got out of style! Hill Engineering Team Members take on the Eras Tour

The anticipation had been building for months, and finally, the day arrived. Robby, Camille, and Ryan, members of the Hill Engineering team, embarked on a journey through time as they attended the Taylor Swift Eras Tour concert in Santa Clara, California.

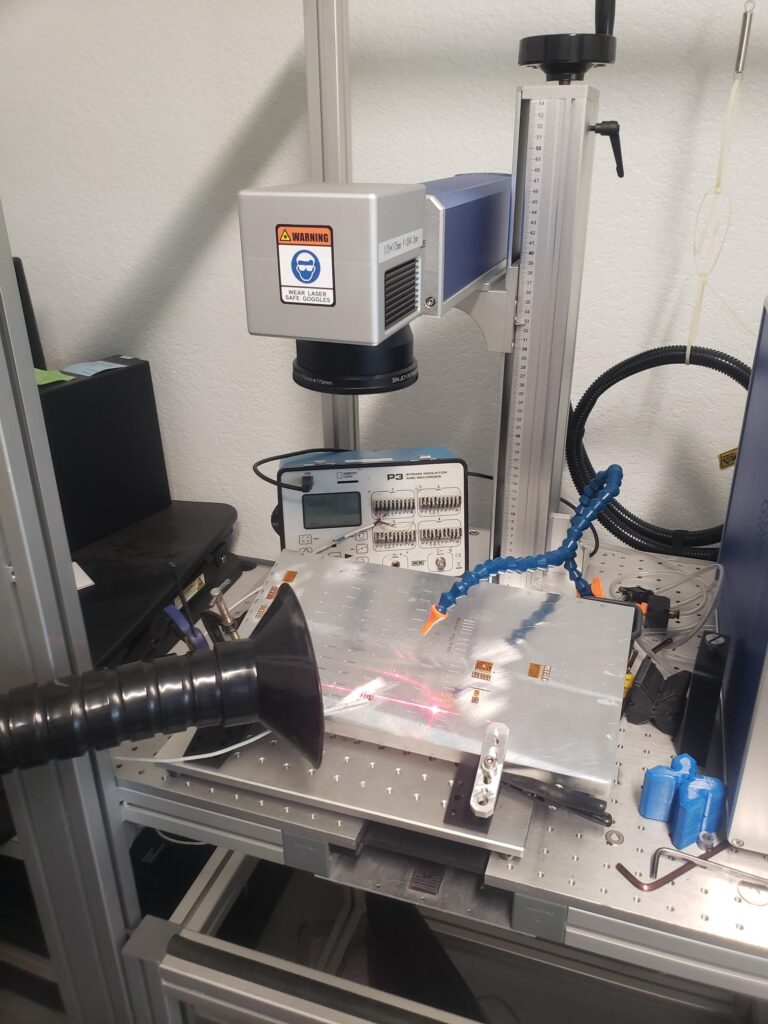

Hill Engineering Acquires New SFX Laser Engraver

Hill Engineering has recently acquired the state-of-the-art JPT MOPA M7 Laser Engraver with a 175x175mm lens and an 80mm Rotary Axis. This strategic investment will improve our laboratory capabilities, enabling us to deliver unparalleled results to our clients!

Continue reading Hill Engineering Acquires New SFX Laser Engraver