Hill Engineering is presenting an overview of our ERS-toolbox® software at the upcoming AFGROW Users Workshop 2017 in Layton, UT. The purpose of the workshop is to provide a forum for users to share ideas, demonstrate how AFGROW is being used for practical cases, and discuss future development. Hill Engineering’s presentation will include an overview of past work where ERS-toolbox® was used to support development of laser peening surface treatments to enhance performance of materials using compressive residual stress. The abstract text is presented below.

Engineered residual stress (ERS) is increasingly being applied as a way to extend the durability and damage tolerance performance of primary structures in various industries including aerospace and power generation. To reduce development costs, reduce the development time, and increase the effectiveness of the final design, methods that accurately predict residual stress for surface treatments are being developed. ERS-toolbox® is a software suite which predicts full field residual stress for a variety of processes including conventional shot peening (SP), laser shock peening (LSP), and cold hole expansion (CX). An overview of ERS-toolbox® will be presented along with example applications.

Details of the ERS-toolbox® software are available on our website. ERS-toolbox®, is the product of more than a decade of meticulous study and collaboration with government and private industry. ERS-toolbox® was successfully applied for design and analysis of a structural retrofit to the F-22 that used laser shock peening to restore performance and extend the service life of the F-22 airframe. ERS-toolbox® offers a fast and flexible approach to design an optimal process for the desired level of compressive residual stress benefit while managing potential detriments from tensile residual stress and process-induced distortion.

The ERS-toolbox® drives innovations in fatigue-life extension by enabling design of processes that provide compressive residual stress, including shot peening, laser peening, and hole cold expansion.

If you are planning to attend the conference please stop by to discuss Hill Engineering’s capabilities in fatigue analysis and design and residual stress measurement. Please contact us for more information.

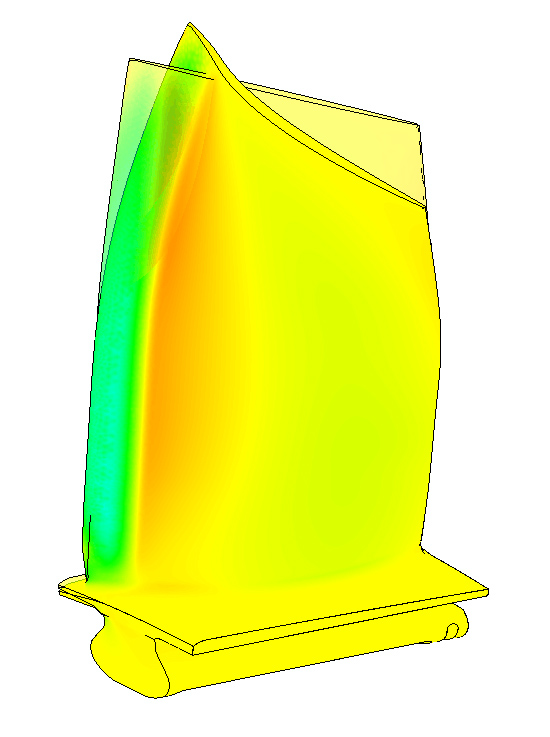

Predicted residual stress and distortion of a high pressure compressor airfoil using the ERS-toolbox.