Hill Engineering is delivering a keynote presentation about the measurement of residual stresses near the surface of peened metals at the upcoming 13th International Conference on Shot Peening (ICSP-13) in Montreal, Canada. The purpose of this conference is to foster exchanges between academic and industrial scientists on processes inducing beneficial residual stress, as well as their effects, with an emphasis on traditional shot peening. Processes like deep rolling, laser peening, ultrasonic peening, cavitation peening, flapper peening and needle peening also fit within the conference’s scope. Hill Engineering’s presentation will include a summary of recent work demonstrating the use of measurements to quantify the near surface residual stress state and to understand its impact on material performance. The abstract text is presented below.

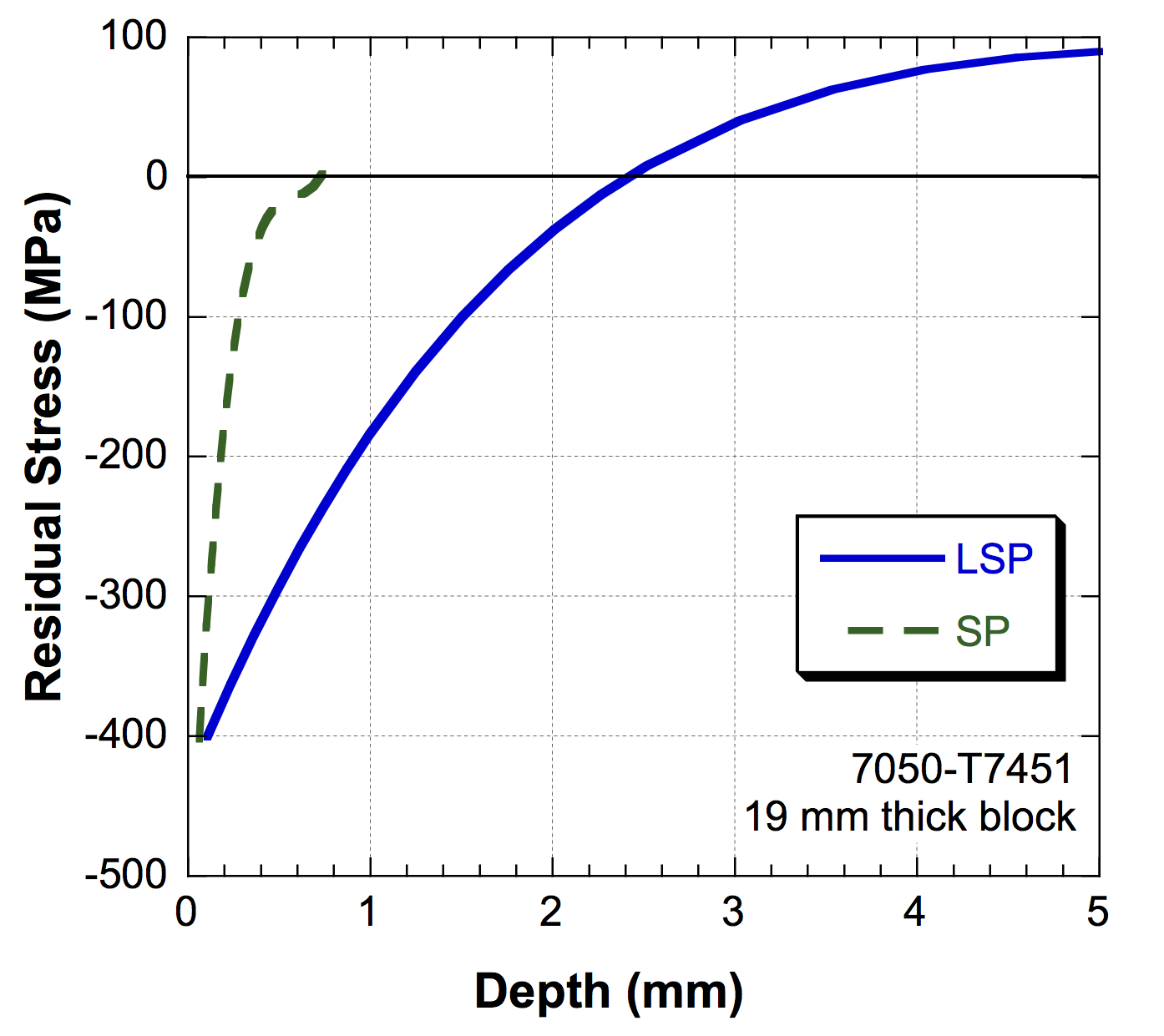

Measurements of residual stress enable forecasts of structural performance that are robust to changes in manufacturing. The details of manufacturing have a significant effect on residual stress near the surface of a finished part. The residual stress subsequently affects subcritical cracking due to fluctuating stress (fatigue) and environmental exposure (environmentally assisted cracking), and may increase or decrease the time required for cracks to nucleate and then the rate of crack growth. Historically, except in special cases, residual stress measurements have not allowed robust measurements of residual stresses that would enable reliable forecasts of component performance. Over the past few decades, residual stress measurement methods have been improved, and put into practice, with demonstrated capability of enabling reliable performance forecasts. We will describe recent efforts that are directed to assess residual stress in shallow layers, such as that induced by shot peening.

If you are planning to attend the conference please stop by to discuss Hill Engineering’s capabilities in fatigue analysis and design and residual stress measurement. Please contact us for more information.

Residual stress produced by shot peening (SP) and laser shock peening (LSP) in 7050-T7451 aluminum (measured by slitting)