Eric Summer and I recently packed up the DART repair tool for a trip down to Naval Base Ventura County in Port Hueneme, CA. There, we participated in the Navy’s Repair Technology Exercise, or REPTX 2022. Onboard the Navy’s Self Defense Test Ship (SDTS), Hill Engineering demonstrated how the DART repair tool can be applied as an industrial maintenance solution.

The DART repair tool is a portable device capable of mapping the surface topology of a part, identify defects, automatically generate a reprofiling tool path to blend out the defect, and perform precision machining to the desired repair profile. The device runs off a local power source, and uses compressed air and a laser profilometer.

We flew to the event in Southern California with the DART. On board the SDTS, we were able to climb down below decks with the DART repair tool on our backs, thanks to the device’s innovative, compact design.

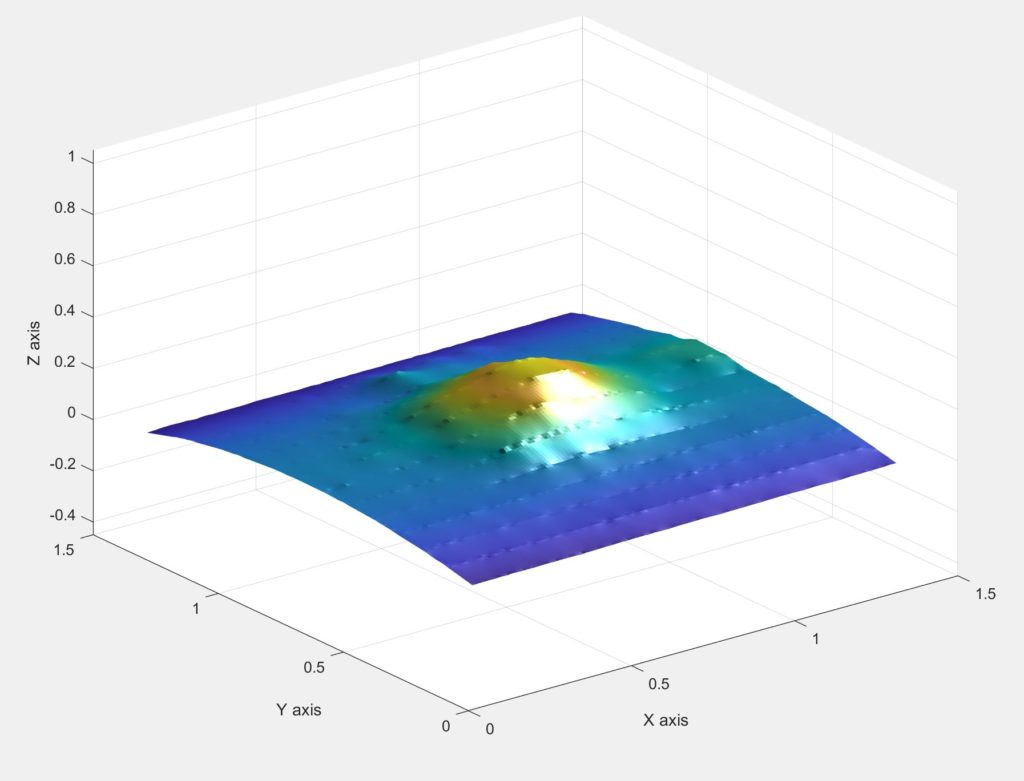

We then mounted the DART to a support post for the ship’s helipad and acquired a 3D map of the surface. The support column was riddled with obtrusions caused by corrosion and surface decay.

Over 60 naval, academic, and industry participants attended the event. It was a great opportunity to showcase the maintenance and residual stress measurement technology being developed at Hill Engineering.

If you have any further questions about the DART repair tool, or any of the other residual stress measurement techniques we perform, please contact us.