Our Rapid Forge Design (RFD) software has generated a substantial amount of buzz since it’s release last year. If you’ve been keeping up with our social media accounts, you’ve probably caught us highlighting its key features and ease of use, especially through our demonstration video in which creator John Watton goes step-by-step through the closed-die impression forging design process.

For those who want a more comprehensive rundown of the software’s features and abilities, as well as plans for future design modules, John recently published an article in Forging Industry Association magazine, where he gives a history of how RFD came to be, and how it serves forgers and forging consumers.

John recognized the need for a domain-specific CAD system for easy forging die design in the early 90s while working for ALCOA. A similar product was in development at the time, which interested and impressed John, though the project was ultimately cancelled.

Surprised that no other such software had been developed to fill this niche that he could find, he decided to take it upon himself to “make it happen,” as we like to say in the Hill Engineering world.

Thus, RFD was born. In the article, John continues by outlining the required software features needed for RFD to be considered a success, as well as future requirements to make the software more robust to fit a wider variety of design parameters.

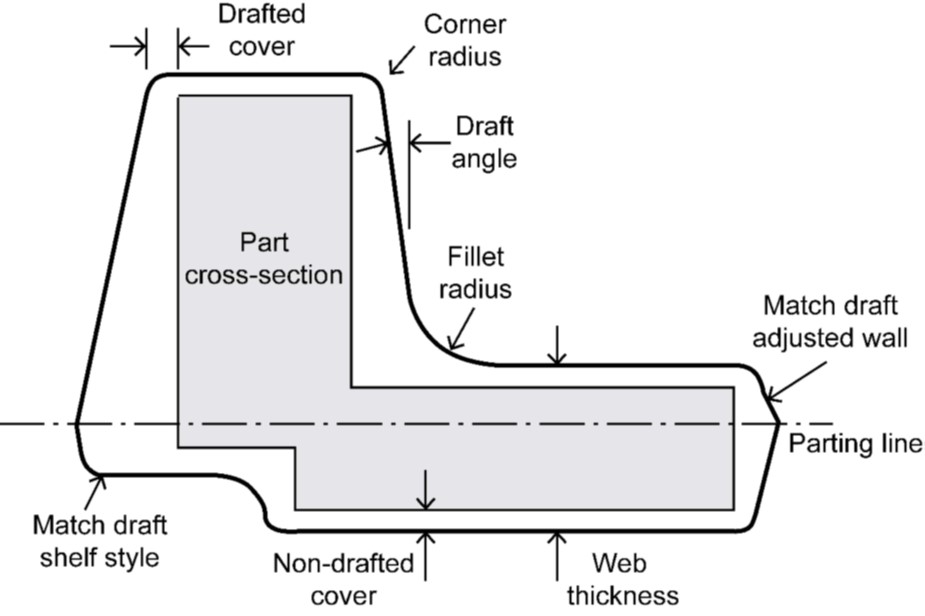

Rapid Forge Design is an automated tool for the fast and reliable design of 2-piece, closed-die impression forgings, which can drastically reduce the time needed to design a forging to industry-accepted guidelines. For the full FIA magazine article, click the link below:

Requirements for a Rapid Forged Part Design Software System

If you have any further questions about RFD and its capabilities, please contact us.