Hill Engineering’s latest brochure shines a spotlight on the ring core residual stress measurement method, a powerful technique for assessing near-surface to bulk residual stress in materials. With its compact footprint and versatility, the ring core method is a robust technique that can be applied under a variety of circumstances.

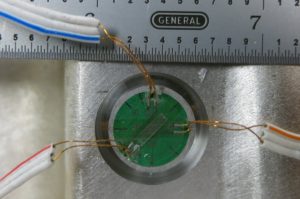

At its core, the ring coring method leverages the principle that residual stress within a material causes deformation when the material is cut. By carefully drilling a core (typically 3-5 mm deep) and measuring the induced strain with metallic foil strain gauges, engineers can calculate the pre-cut residual stress distribution using elasticity principles.

This method is particularly valuable for its broad range of applications.:

- Measuring near-surface residual stress up to 5.0 mm in depth

- Conducting in-situ measurements on large structures and assemblies, making it ideal for fieldwork

- Providing cost-effective and efficient assessments when time and budget constraints are critical

- Capturing multiple stress components, including in-plane principal stresses.

Hill Engineering’s brochure emphasizes that ring coring is not only a technical solution but also a practical one, offering precision without sacrificing cost-efficiency. This method is poised to enhance industries where understanding stress distribution is crucial—such as aerospace, automotive, and infrastructure.

Explore how the ring core method can benefit your approach to residual stress analysis by diving into Hill Engineering’s free brochure here or on the ring core method page. For further information about the ring core method, or any of our other residual stress measurement techniques, please contact us.