-

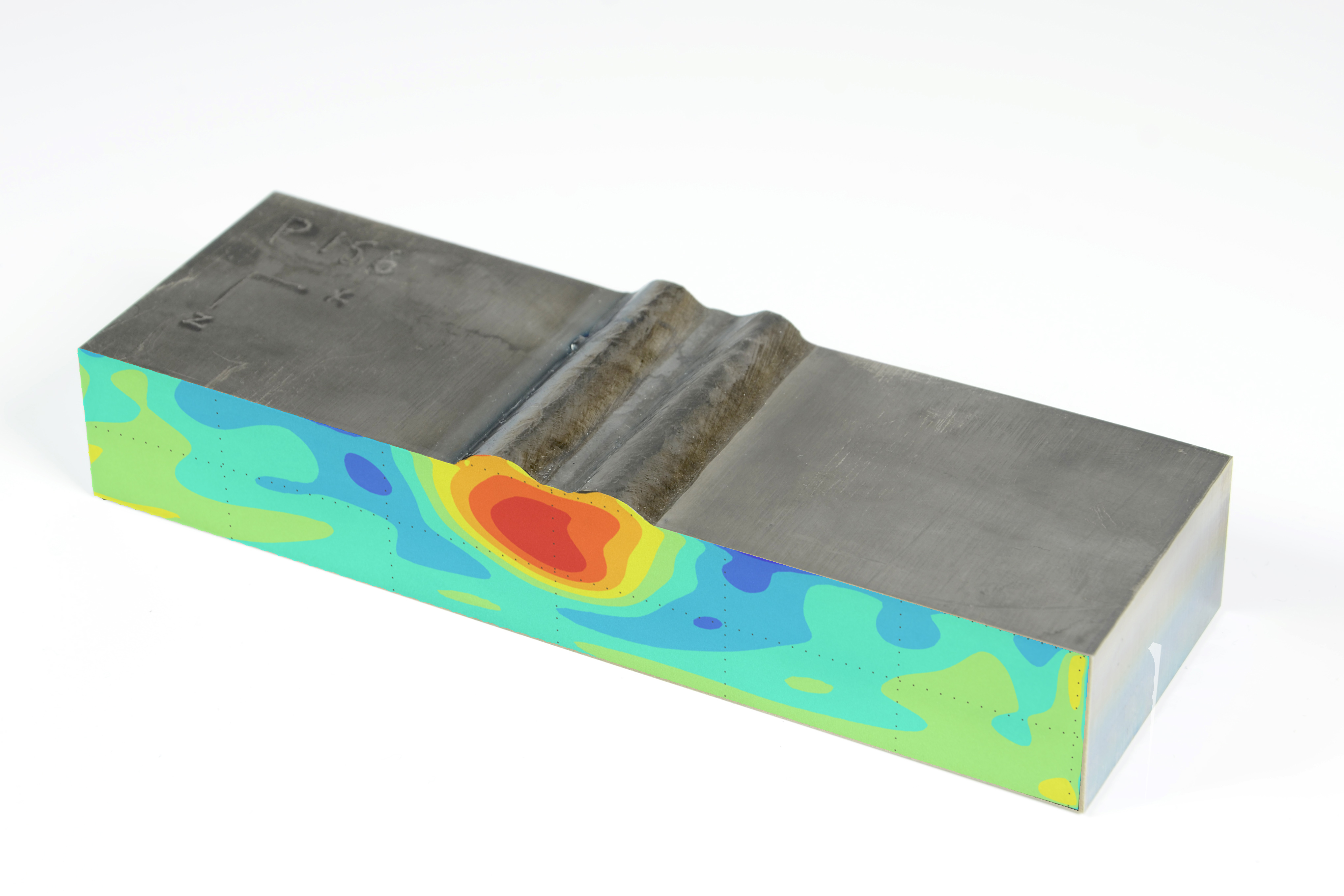

Hill Engineering has published a new technical case study, Effects of Trimming on Welded Pipe Residual Stress Measurements, exploring how sectioning on a welded pipe influences the residual stress state within the weld region and what that means for accurate measurement planning. Residual stress from welding plays a critical role in structural performance, combining with…

-

2016 was an exciting year at Hill Engineering. We accomplished so much and we wanted to take a moment to recognize some of the highlights. Early in the year, we were in the middle of Hill Engineering’s largest ever facilities planning/construction project. We had just selected our new office location and needed to plan and…

-

If you’ve been looking for an overview of our expedited residual stress measurements through our ExpressRS® service, look no further. Our new brochure highlights the many ways that ExpressRS® can help you reach your project’s goals. When choosing ExpressRS®, your measurements are given priority in our laboratory, making it possible to meet your deadline sooner.…

-

Every summer, Hill Engineering hires university students as interns; aiming to give them insight into industry jobs and provide them with the experience they’ll need to develop their careers post-graduation. We pride ourselves on involving interns in projects which utilize and further explore the concepts they have learned in school. In the past, we’ve had…

-

Hill Engineering is proud to announce that we have been awarded Canadian Patent No. 3080749, titled Analysis to Enable Stress Relief in Material Under Stress, for our DART™ near-surface residual stress measurement device. Residual stress analysis has traditionally been limited to static, laboratory-based environments, where controlled conditions allow for precise measurements. However, performing accurate and…

-

Hill Engineering will be presenting at the upcoming Propulsion Safety & Sustainment Conference (PS&S) in Phoenix, AZ on May 22nd through May 25th. We invite you to come see us. We will be sharing some recent work about experimental validation of process models for nickel engine disk design. Hill Engineering’s presentation will include a summary…

-

Hill Engineering had a strong presence at the International Conference on Residual Stress (ICRS) 2025, showcasing our precision engineering, residual stress testing expertise, and software suite. The DART (Device for Automated Residual stress Testing) took center stage, drawing steady crowds for live demonstrations of its automated near-surface measurement capabilities. Attendees saw firsthand how automation improves…

-

Hill Engineering is presenting about residual stress engineering to support fleet management and life extensions of legacy fleets at the upcoming 2017 Aircraft Airworthiness & Sustainment Conference (AA&S) in Phoenix, AZ. The mission of this conference is to identify the challenges and the collaborative work being done within the aerospace community in improving the safety,…

-

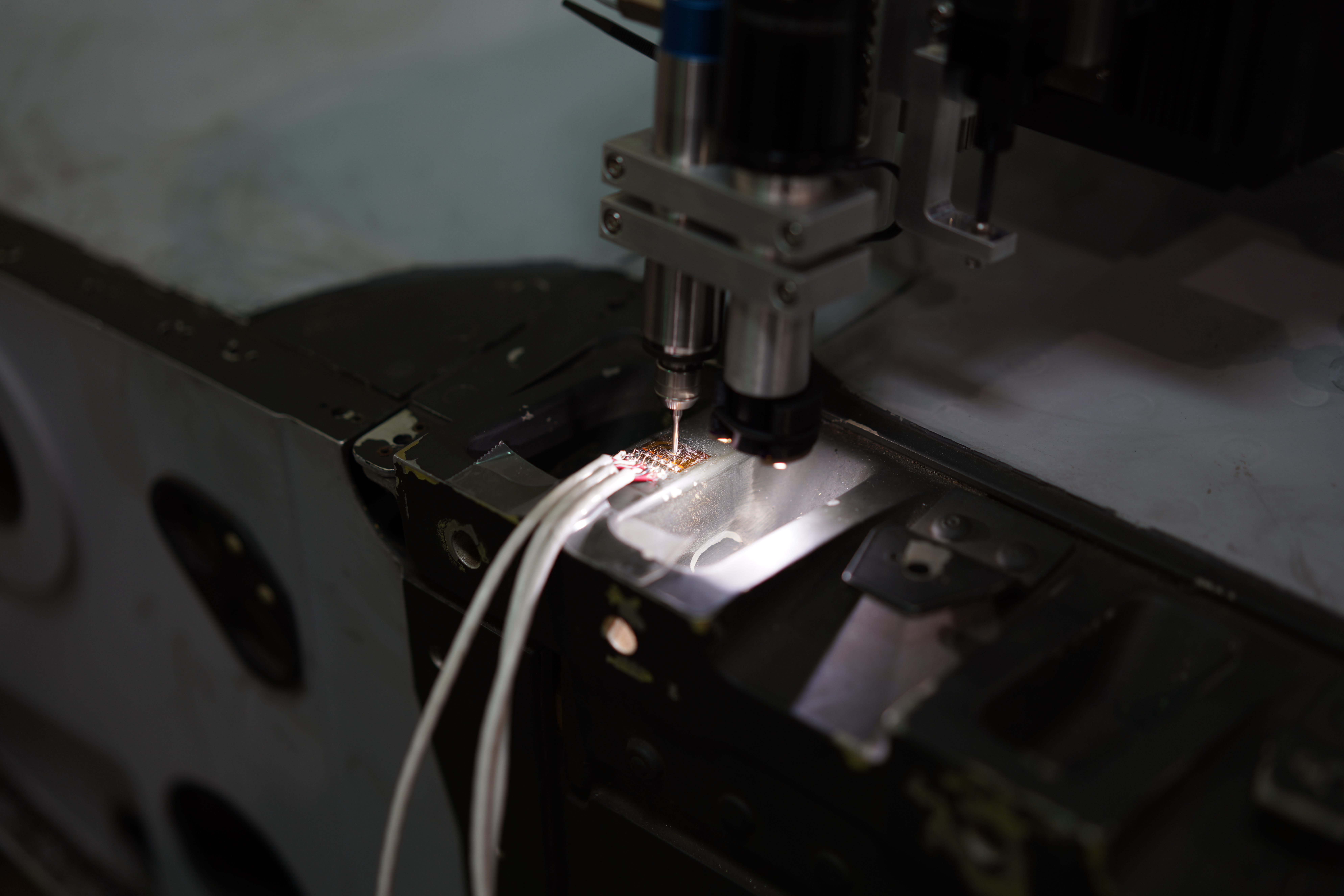

Hill Engineering is proud to announce that onsite hole drilling residual stress measurements have been added to our growing scope of ISO/IEC 17025 accredited measurements. These are the same high-quality hole drilling measurements that Hill Engineering is known for, but now with the option of being ISO/IEC 17025 accredited, which may help to meet internal…

-

We would like to welcome Josh Hodges to Hill Engineering. Josh has worked in the United States Air Force T-38 ASIP office (Hill Air Force Base) for the past 8+ years as a Structural Integrity Analyst. During his time in the T-38 ASIP office, Josh filled many roles including: developer of the Broad Application for…