A new Hill Engineering article titled “Near Edge Residual Stress Measurement Using Incremental Hole Drilling” has been published online in Experimental Mechanics. This study examines the effects of performing a hole drilling residual stress measurement near the free edge of a specimen. Below is the abstract text.

Background

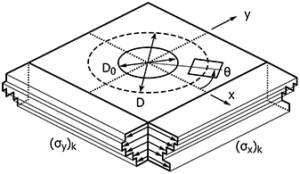

Hole drilling is a measurement technique used to determine near surface residual stresses and has been codified in ASTM E837. In ASTM E837-20, the minimum allowable distance to a free edge is prescribed as 1.5 times the gauge circle diameter.

Objective

This work examines the effect arising from the distance from a free edge on a hole drilling measurement and provides an approach to determine residual stress for measurements where the edge distance is closer than that currently permitted by ASTM E837-20.

Methods

Numerical experiments were performed to understand how the compliance matrices change when the distance from a hole drilling measurement to a free edge varies. In addition, a series of hole drilling measurements were performed at various distances from a free edge using a shot peened aluminum plate with a nominally equibiaxial stress state to demonstrate the approach.

Results

The numerical experiments determined that the use of corrected compliance matrices is appropriate when the edge distance is as small as 0.35 times the gauge circle diameter. Physical measurements supported the use of custom compliance matrices for a given free edge distance and specimen thicknesses.

To read the full article text, click here.

For more information about our capabilities with the hole drilling method, please contact us.