Our latest brochure highlights the Deep-Hole Drilling (DHD) residual stress measurement method, a specialized technique with applications across multiple industries, including aerospace, automotive, and heavy manufacturing.

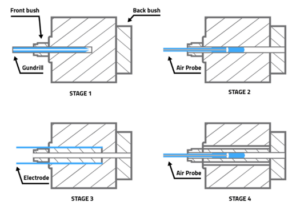

The Deep-Hole Drilling measurement method can be used to determine bulk residual stresses in large parts up to 750 mm thick. Through the drilling of a reference hole and measuring its diameter before and after stress release, DHD allows for the precise calculation of residual stress profiles. This method is not only suitable for laboratory conditions but can also be applied in the field, making it highly versatile for a variety of projects.

Hill Engineering’s long-standing expertise and commitment to precision make us a trusted partner for many residual stress measurement techniques, including the Deep-Hole Drilling method. With cutting-edge technology and a team of experienced engineers, Hill Engineering ensures top-quality results, whether in the lab or in the field.

You can download the DHD Brochure here.

For more information on the Deep-Hole Drilling method and how it can be applied to fit your residual stress measurement needs, please contact us.