Hill Engineering’s Rapid Forge Design™ software is an automated tool for fast and reliable design of 2-piece, closed-die impression forgings. Rapid Forge Design™ reads the final part geometry and automatically designs a forging according to accepted industry guidelines and user inputs. Rapid Forge Design™ is intended for use by forging suppliers and forging consumers/OEMs.

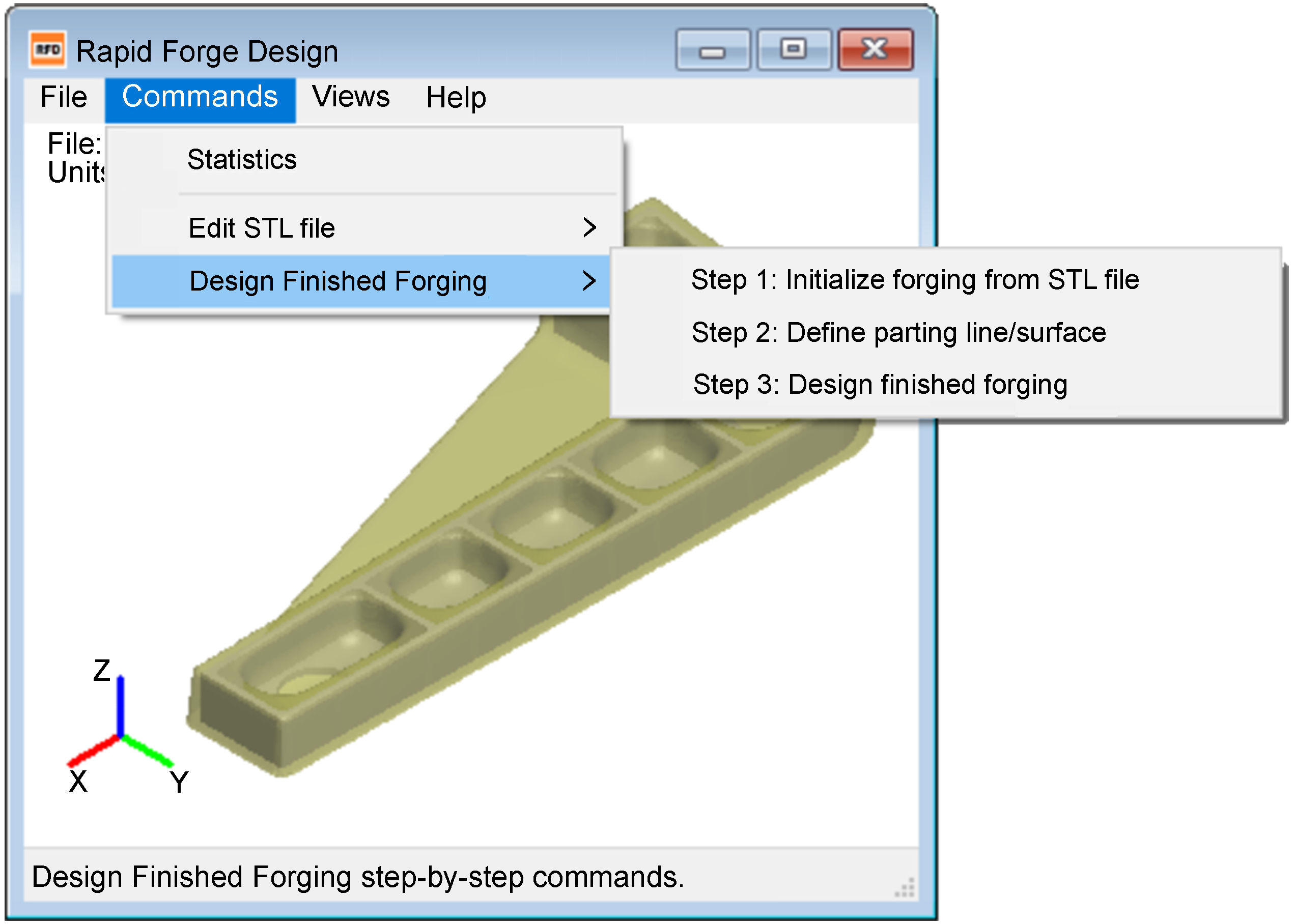

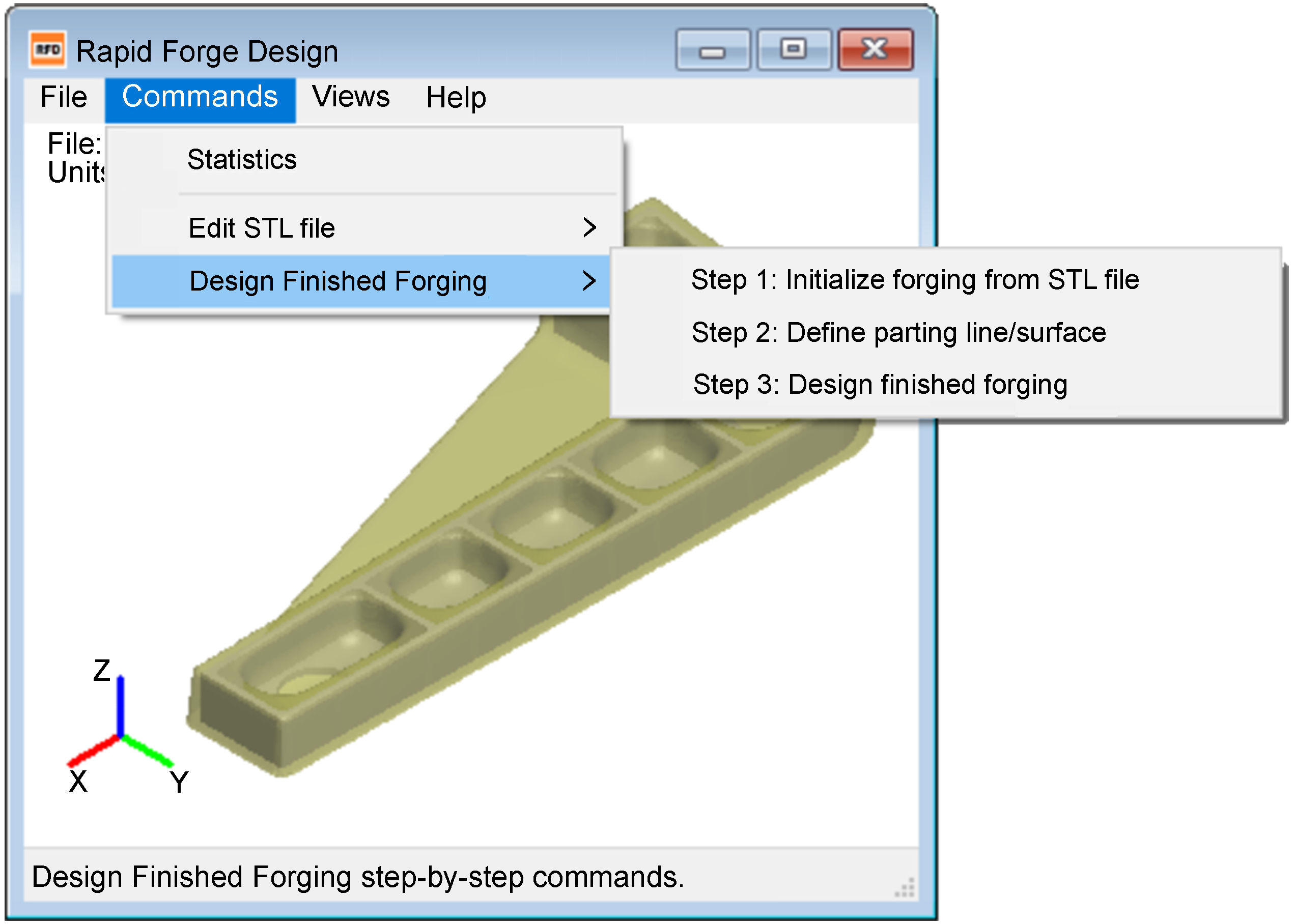

The Rapid Forge Design™ software comes with a user-friendly, graphical interface that allows for forging designs using a simple, 3-step, menu guided approach.

Illustration of Rapid Forge Design™ user interface

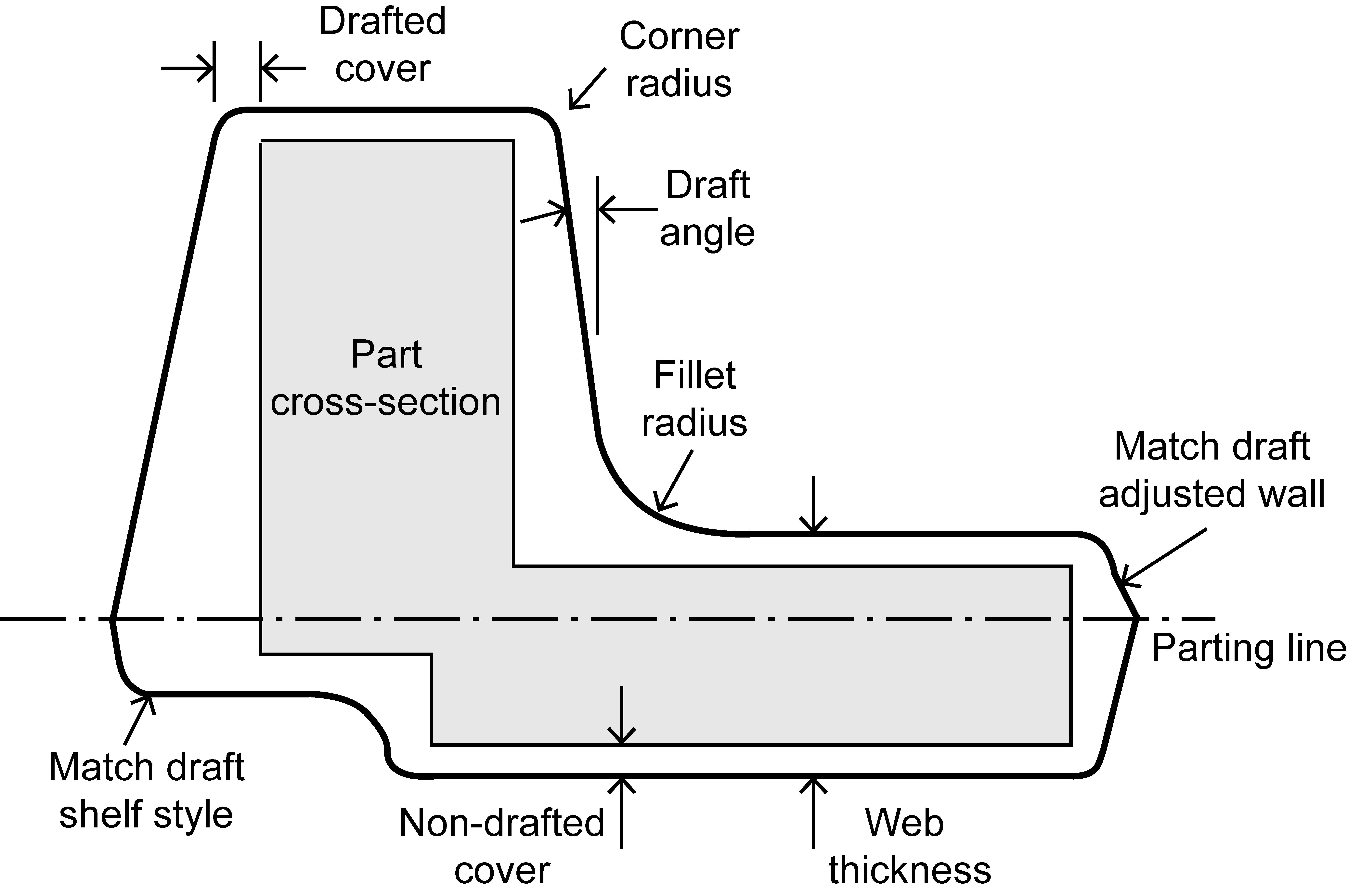

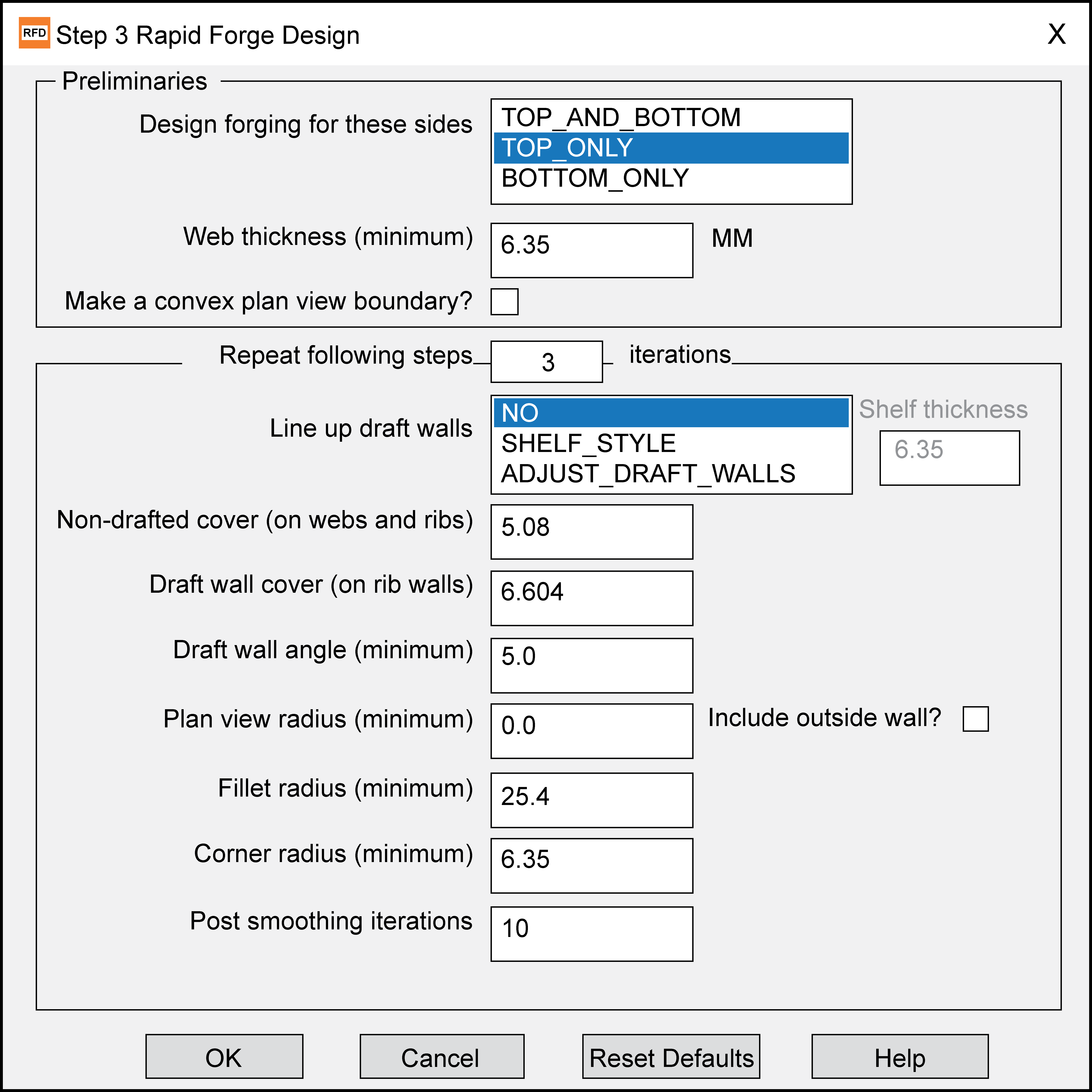

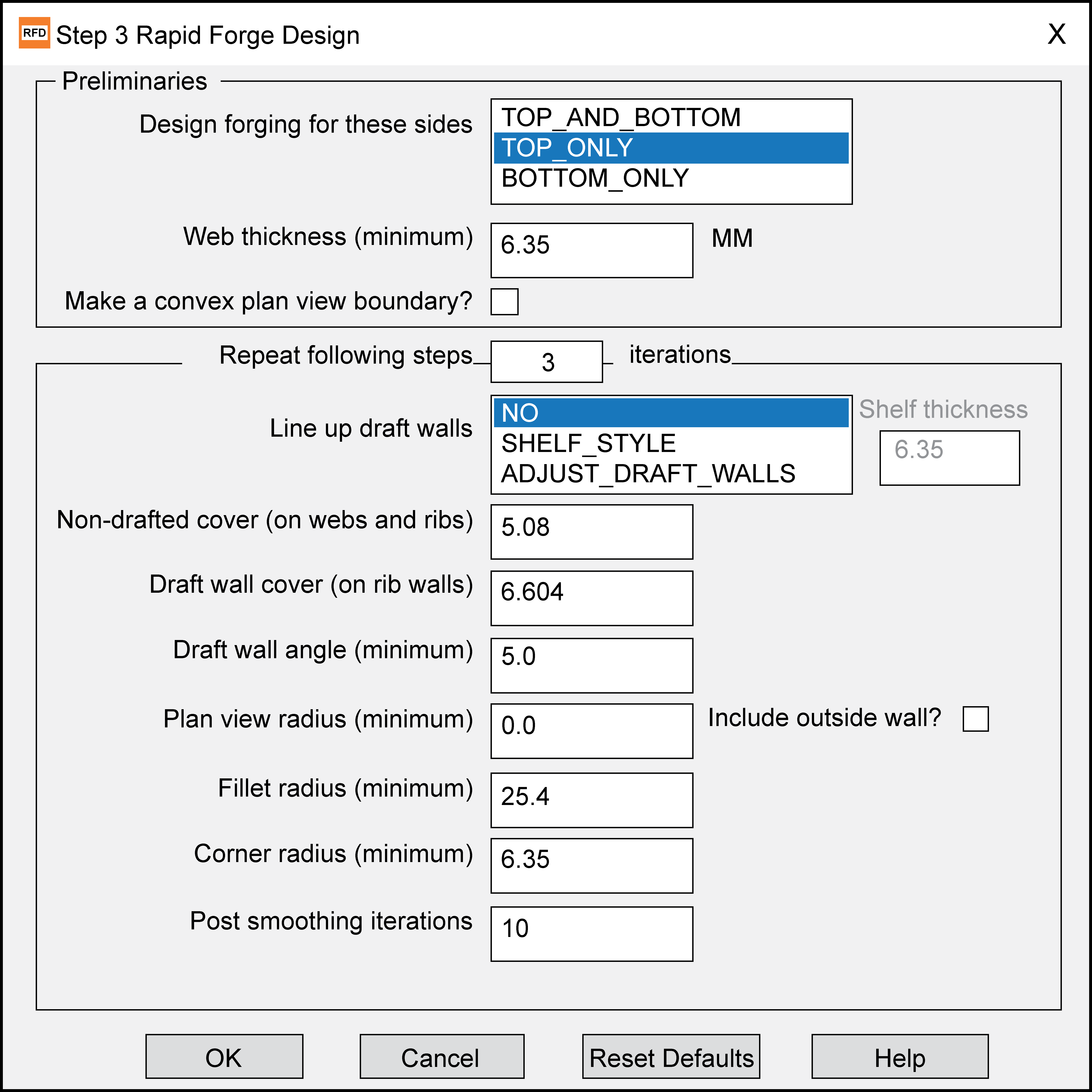

The inputs to Rapid Forge Design™ are the 3D geometry of the machined part (to be manufactured from the forging) and critical, user-defined parameters that allow for customization of the resulting forging design (e.g., minimum thickness and minimum radius values).

The forging design is generated by Rapid Forge Design™ according to a set of prescribed, industry-accepted design rules. After the user inputs are provided, the automated forging design process is completed by Rapid Forge Design™ in minutes without any further user intervention. With this approach, Rapid Forge Design™ enables the design of forgings with significantly less effort than existing manual processes.

Rapid Forge Design™ outputs the 3D geometry of the forging and a host of useful forging statistics and properties including volume, plan view area, periphery length, heat treatment section thickness, and other dimensional information. These metrics are essential to support the quoting process (material producers) and planning and costing activities (OEMs).

The preliminary forging designs produced by Rapid Forge Design™ can be used as the starting point for the finished forging’s more detailed design and tooling CAD files.

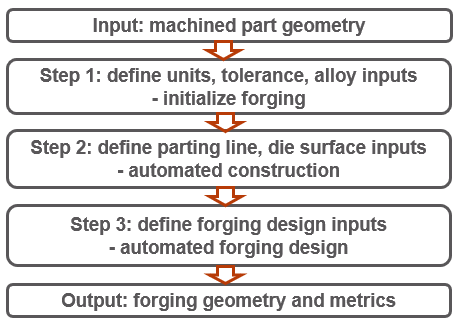

The Rapid Forge Design™ process is outlined in the flowchart below. The operator can input and customize important design parameters including: web thickness, draft wall cover, draft wall angle, plan view radius, fillet radius, and corner radius. Default values are provided based on alloy dependent industry standards. Help menus provide additional support and guidance, where necessary.

Summary of Rapid Forge Design™ workflow

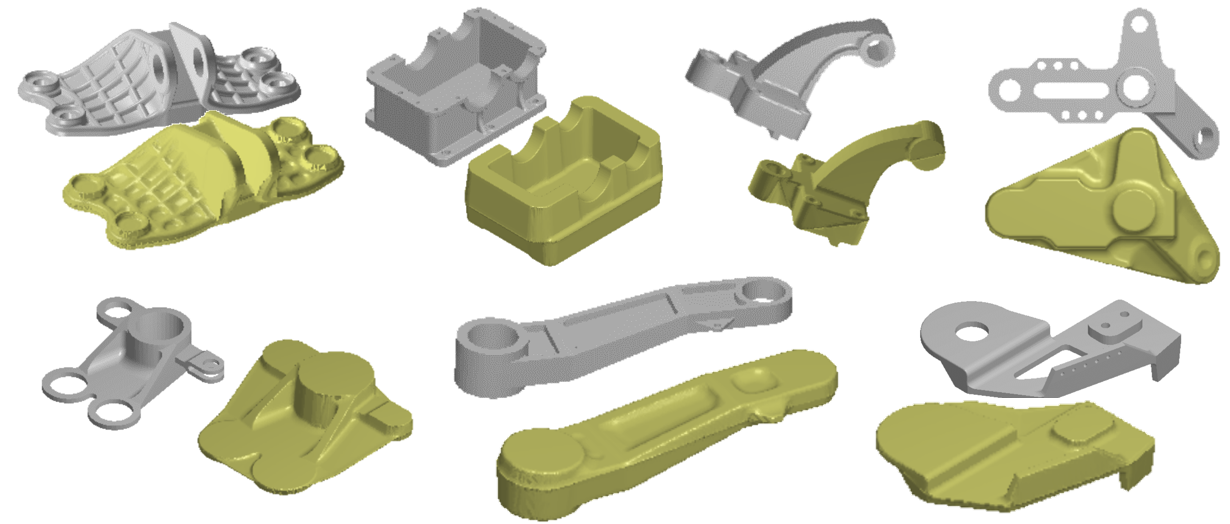

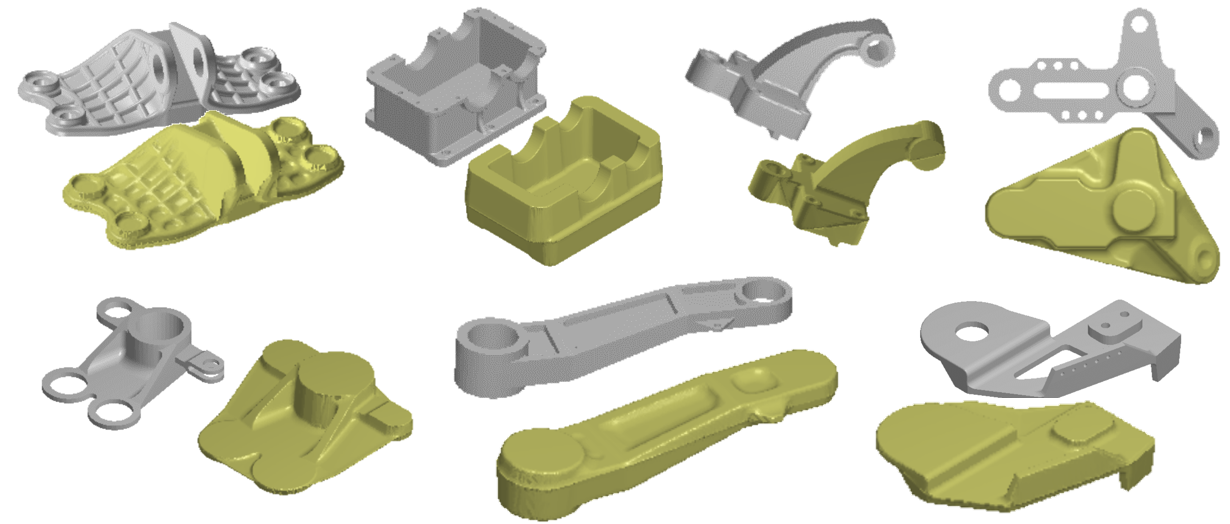

Numerous examples taken from publicly available CAD files come with the software. The following are a few illustrations showing the ability of Rapid Forge Design™ to effectively produce forging designs for a wide variety of supplied final part geometry.

Illustration of forging designs produced by Rapid Forge Design™ (gold) along with the final machined part geometry that was used as the input for design (grey)

https://www.youtube.com/watch?v=wV3Vb4-DUV4

To place an order for Rapid Forge Design™ related goods and services, please contact us.