As we discuss in a related case study, aluminum alloy heat treatment is a three-step process designed to achieve the desired properties. The process involves: 1) solution heat treatment (SHT) at an elevated temperature below the melting point, 2) quenching in a tank of fluid (e.g., 140-180°F water), and 3) age hardening. While providing good properties, the heat treatment has the negative side effect of creating bulk residual stress and distortion. These side-effects are a direct result of non-uniform cooling during the rapid quench. One approach to mitigate this problem is the application of a post-heat treatment mechanical stress relief process. In addition to modeling the heat treatment process, our analysis tools can support evaluation and optimization of mechanical stress relief processes.

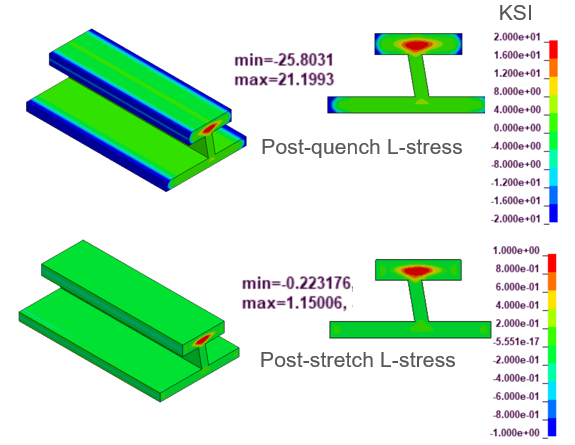

Mechanical stress relief is practical for many aluminum alloy products as a means of reducing bulk residual stress. For products with a uniform cross section, such as most extrusions, plate, and bar stock, the material can be stretched on the order of 1% to 5% using special equipment. The figure below shows an example extrusion section with bulk residual stress (top) along with the remaining residual stress after mechanical stress relief (bottom). Note, the use of different color scales because the residual stress magnitude changes so significantly. This figure illustrates our capability to model post-quench and post-stretch residual stress.

Illustration of predicted post-quench (top) and post-mechanical-stress-relief-stretch (bottom) in the long direction of an example aluminum extrusion

For other products such as forgings, an alternative stress-relief process using a compressive cold work stress relief can be employed. For a hand forging this is usually achieved using open-dies comprised of mostly flat surfaces. Post-quench, the hand forging is subjected to 1% to 5% compression often in an overlapping fashion.

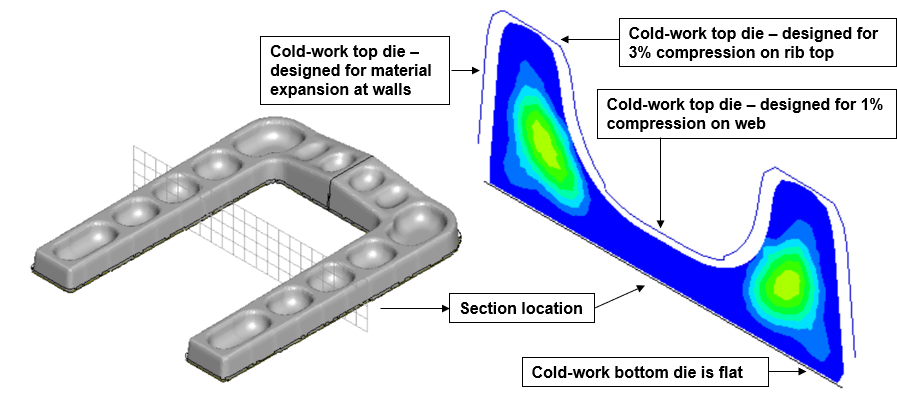

On the other hand, an impression-die forging usually requires a more complex process that involves a cold-work die set. Such die sets are designed to impress 1% to 5% cold-work. Typically, the compression is on the order of 1% in thinner web sections and 3% in thicker rib sections. Since the forging will be at room temperature for the compression (therefore the term – cold-work) it does require higher press loads than one sees in the hot forging operation. The following figure illustrates the elements of a cold-work die set.

Illustration of a typical cold-work die set for mechanical stress relief of an aluminum forging

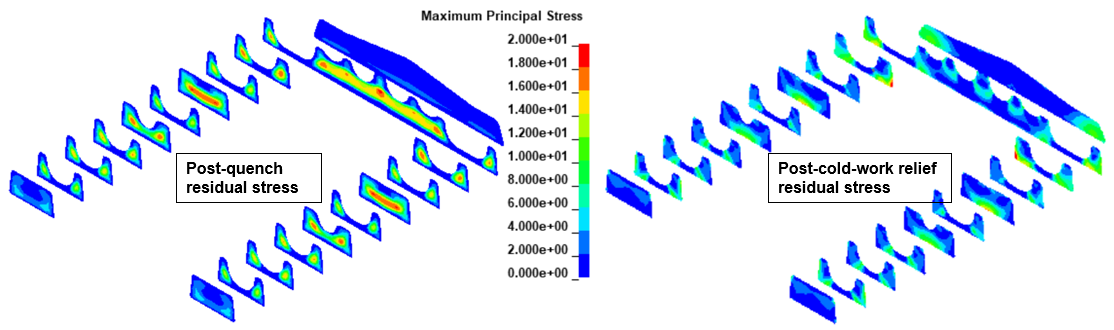

In a previous case study, we demonstrated our capability to predict post-quench residual stress and distortion for an example forging. The effect of mechanical stress relief using compression dies on that same example forging is shown below. The post-quench residual stress (left) reaches as high as 20.0 ksi in this aluminum 7075 simulation. The post-cold-work residual stress (right) is significantly reduced. The reduced residual stress level in the stress-relieved state has significant advantages in terms of ease of machining (reduced distortion) and improved part performance.

Predicted residual stress post-quench (left) and post-cold-work-stress-relief (right) for an example aluminum forging

If this example relates to your production challenges, or if you have any questions about how these results might affect your projects, please do not hesitate to contact us. We would also be happy to answer any questions that you may have.