TrueSlot® is an innovative technique for measuring near-surface residual stress that is more reliable than conventional techniques.

TrueSlot® is a residual stress measurement technique for generating a profile of residual stress versus depth from the material surface. The stress computation is similar to slitting but offers more sensitivity near the surface due to the proximity of the strain gage.

Additionally, TrueSlot® is globally less invasive than slitting because the volume of removed material is localized to the surface and does not typically extend through most of the specimen thickness.

The physical application of TrueSlot® is like hole drilling, however instead of a shallow hole being milled into the body of a specimen containing residual stress, the material removed is a shallow slot. The strain released with each incremental slot depth is measured near the slot using a strain gage.

TrueSlot® is useful for

- Production quality control applications

- Applications requiring in-field measurements with portable equipment

- Near-surface residual stress determination

- Parts with large or complex geometry

- Applications with challenging measurement access

- Applications requiring rapid turn time

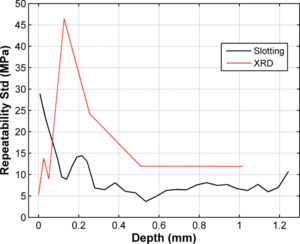

TrueSlot® was found to have better repeatability when compared with conventional x-ray diffraction.

You can read about our repeatability study here.

TrueSlot® measurements are performed using our DARTTM system for automated residual stress measurement.