Aluminum alloy heat treatment is a three-step process designed to achieve desired properties. The process involves: 1) solution heat treatment (SHT) at an elevated temperature below the melting point, 2) quenching in a tank of fluid (e.g., 140-180°F water), and 3) age hardening. While providing good properties, the heat treatment has the negative side effect of creating bulk residual stress and distortion. These side-effects are a direct result of non-uniform cooling during the rapid, time-dependent quench. Since there is an unavoidable difference in cooling rates between near-surface and internal areas, thinner versus thicker sections, locations first submerged versus those submerged last, and vertical versus horizontal surfaces, the generation of bulk residual stress and distortion is unavoidable. Oftentimes there are so many variables in play it can appear as though there is a high degree of randomness in the process if things are not carefully controlled. Our analysis tools can help.

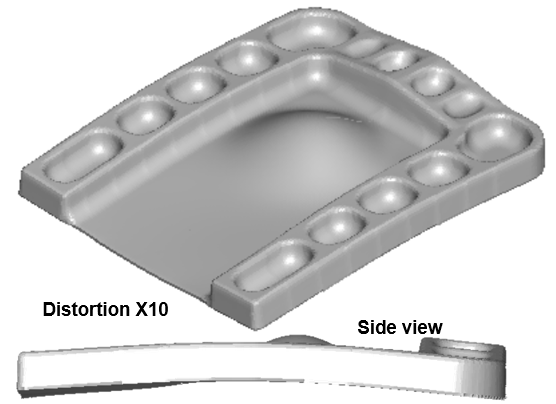

The focus of this case study is the quench distortion of an aluminum aerospace forging. Using our modeling tools, we were able to capture the significant post-quench distortion in the forging, which is shown in the figure below. A rapid immersion quench, evenly applied, results in a very distorted and bowed output.

Illustration of predicted distortion of an aluminum forging during quench

Clearly, alternatives needed to be explored to mitigate the large amount of distortion. We considered several possibilities: slowing the cooling on one side (with a coating), removing the webbing before the quench (with machining), increasing the thickness of the webbing, or redesigning the forging with back-to-back symmetry by putting two parts into one forging. However, real-time physical experimentation of multiple options would be expensive and time consuming.

With modeling tools, we were able to quickly and effectively identify the most promising alternatives for improvement.

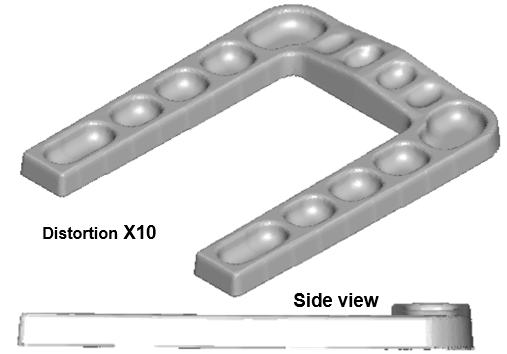

In this case, the biggest improvement came from removal of the webbing. The webbing is necessary for some of the initial forging operations, but does not need to be retained. It does not provide any coverage of the customer’s final post-machined part, and it is not necessary for heat treatment. Removing the webbing (i.e. cutting it off) prior to heat treatment requires an extra machining operation, but that is relatively inexpensive. As seen in the next figure, removing the webbing before quench resulted in a post-quench distortion that is remarkably reduced.

Illustration of predicted distortion for an alternate aluminum forging quench process that involves removing the webbing from the center prior to solution heat treatment and quench

The advantage of pre-production simulation is that problems can be found and solved beforehand, and the robustness of the proposed solutions can be tested and quantified.

Post-quench distortion is driven by bulk residual stress. That stress is created during the quench due to uneven cooling. Near surface cooling is much faster than the internal cooling of the part. This is unavoidable. However, using our modeling tools, the quench-induced residual stress can be predicted.

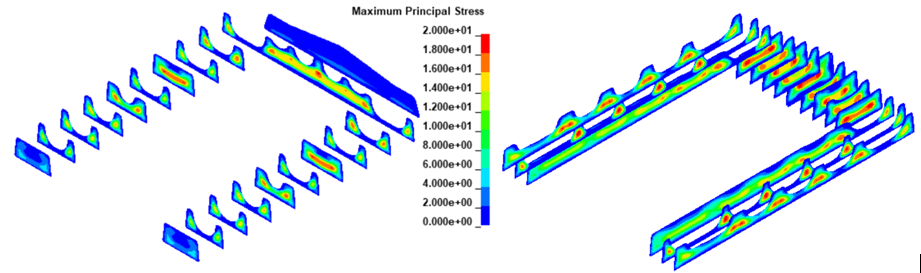

This predicted bulk residual stress is useful in follow-up simulations of post-machining distortion and part performance. The next figure shows the principal bulk residual stress as seen in section planes throughout the forging. Note that the residual stress reaches as high as 20.0 ksi in this aluminum 7075 simulation. This residual stress is post-quench and absent of any mechanical stress relief operations that are typically performed in subsequent steps.

Illustration of predicted post-quench bulk residual stress in an aluminum forging

If this example relates to your production challenges, or if you have any questions about how these results might affect your projects, please do not hesitate to contact us. We would also be happy to answer any questions that you may have.