Today marks a major milestone in the field of residual stress measurement. The contour method, one of the most useful and advanced residual stress measurement techniques, was first successfully implemented on this date (August 16th) in 1999 by Mike Prime at Los Alamos National Laboratory. The most significant feature of the contour method is its ability to generate detailed two-dimensional residual stress maps like the one shown below. Please join us in wishing the contour method a very happy 18th birthday!

As we’ve noted previously, Mike originally conceived of the contour method concept in early 1999 and soon after performed some preliminary analytical studies and simplified experiments (on a specimen that had been previously cut in half for slitting measurement) to further investigate the approach. An attempt was made to measure the weld residual stress, using the contour method, in a test specimen in June 1999. This test encountered experimental difficulty and was never published. But Mike wasn’t deterred and on August 16, 1999, the team at Los Alamos National Laboratory successfully cut a plastically bent beam of 21Cr-6Ni-9Mn austenitic stainless steel with a known residual stress profile. This cut lead to the first contour method publication and marks a major milestone in the history of residual stress measurement.

We began working with the contour method at UC Davis in 2000 and further refined and developed the measurement technology. Soon after Hill Engineering was founded, we licensed the contour method technology from Los Alamos National Laboratory in 2006, recognizing the potential of the technique. Over the past eleven years Hill Engineering has successfully applied the contour method to measure residual stress for a range of applications including: weld residual stress, laser peening, and cold expanded holes. Many of these residual stress measurements have been performed in support of programs related to fatigue analysis of critical structure.

Please contact us for additional information about the contour method or other residual stress and material performance issues.

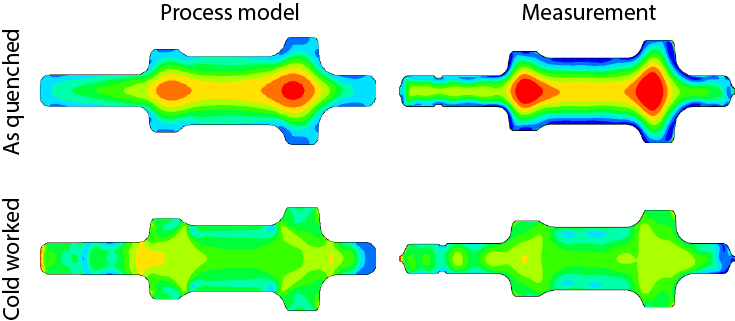

Example contour method measurement results from an aluminum die-forging