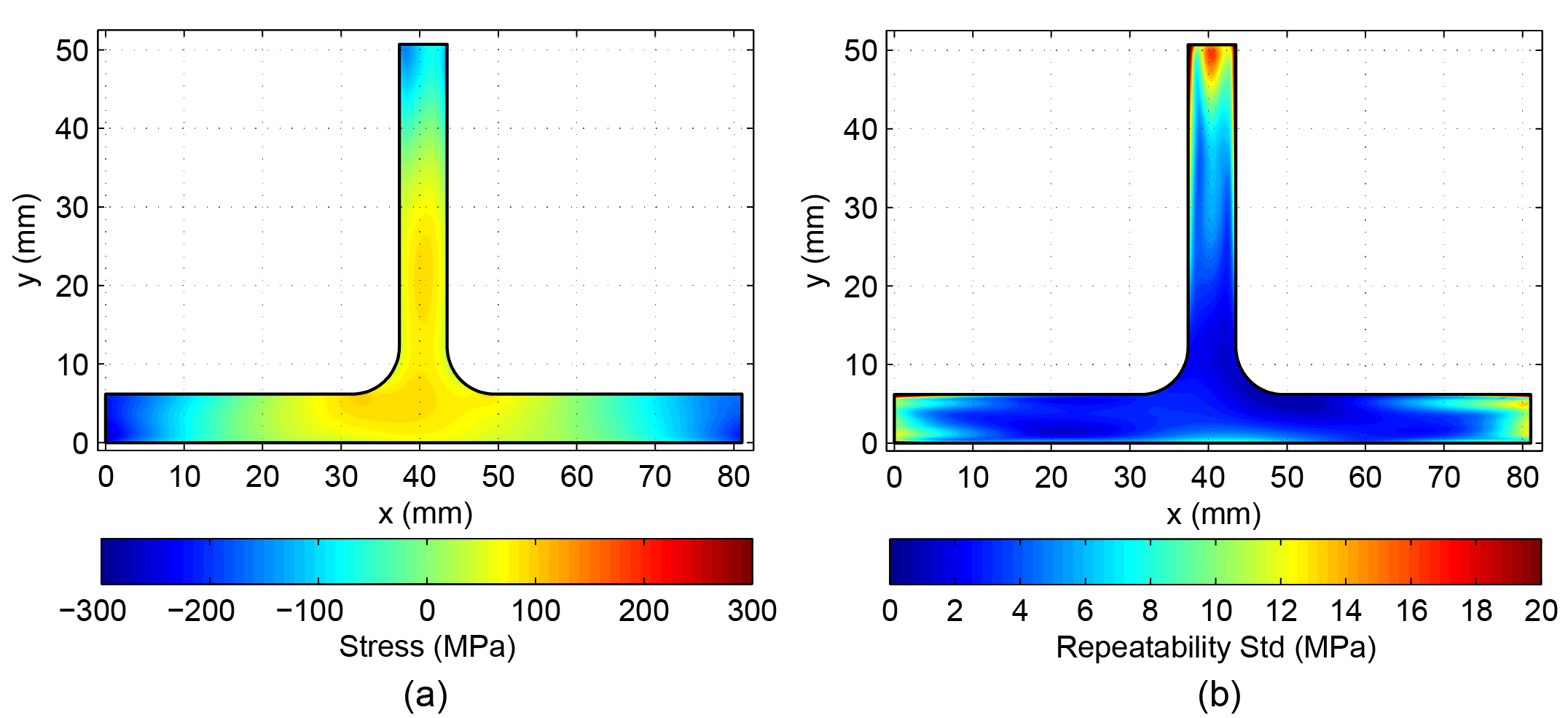

Recently, Hill Engineering posted a new case study detailing our research into contour method repeatability. In the case study, we performed contour method measurements on multiple similar specimens belonging to six different specimen types: aluminum T-section, stainless steel plate with dissimilar metal slot-filled weld, stainless steel forging, titanium plate with electron beam slot-filled weld, nickel disk forging, and aluminum plate.

Five to twelve measurements were run in each group, and afterward residual stress analysis was performed to determine a repeatability standard deviation for each population. As expected, the results for specimens within the groups were similar, leading to a relatively small standard deviation throughout the part interior with localized regions of higher standard deviation along the surface perimeter.

For a more detailed look, please read the full case study. For more information about our contour method residual stress measurement capabilities, please contact us.

(a) Mean and (b) repeatability standard deviation for the aluminum T-section specimens