You might recall a previous post introducing the Integrated Maintenance System, or IMx+ system, that uses next generation technologies to address the quality assurance needs of the aerospace industry. We’re happy to announce that the IMx+ system is now authorized to operate and connect to the USAF NIPRNET, a huge milestone for Hill Engineering and all groups involved.

Continue reading IMx+ system receives ATO from USAFHill Engineering Blog

Inside Hill Engineering’s Quality Control Program

In a previous post, we highlighted the steps we took to develop a Quality System that is compliant with ISO. Since then, we have successfully completed three renewal audits and are currently accredited to ISO/IEC 17025:2017, the most recent revision of the standard. Part of our Quality System requirements includes the creation and maintenance of a quality control program for the various residual stress measurement techniques we perform in our laboratory. Consistently providing high quality results to our customers is something we pride ourselves in and the best way for us to assure that is through a quality control program.

Continue reading Inside Hill Engineering’s Quality Control ProgramHunting for Meteors at Caswell Memorial State Park

Nothing sums up summer quite like a good camping trip. A handful of Hill Engineering families made their way to the Stanislaus River and Caswell Memorial State Park for a weekend of nature, campfires, and s’mores.

Continue reading Hunting for Meteors at Caswell Memorial State ParkAS7045 – Residual Stress Measurement and Classification, Metallic Structural Alloy Products and Finished Parts

A new Aerospace Standard, AS7045 – Residual Stress Measurement and Classification, Metallic Structural Alloy Products and Finished Parts, was recently published by SAE International. Hill Engineering was actively involved in the development of the standard along with many of our collaborators in the aerospace industry. AS7045 offers tremendous potential to revolutionize the management of residual stress during metallic material procurement.

Continue reading AS7045 – Residual Stress Measurement and Classification, Metallic Structural Alloy Products and Finished PartsWe never got out of style! Hill Engineering Team Members take on the Eras Tour

The anticipation had been building for months, and finally, the day arrived. Robby, Camille, and Ryan, members of the Hill Engineering team, embarked on a journey through time as they attended the Taylor Swift Eras Tour concert in Santa Clara, California.

Overcoming Challenges in Residual Stress Measurements on Small Test Specimens Using the Slitting Method

When it comes to measuring residual stress in small test specimens, precision is paramount. The slitting method is well suited to this application due to the high accuracy of wire EDM machining. However, this method is not without its challenges, especially when applied to very small test specimens, such as the 0.022-inch diameter wire we recently measured.

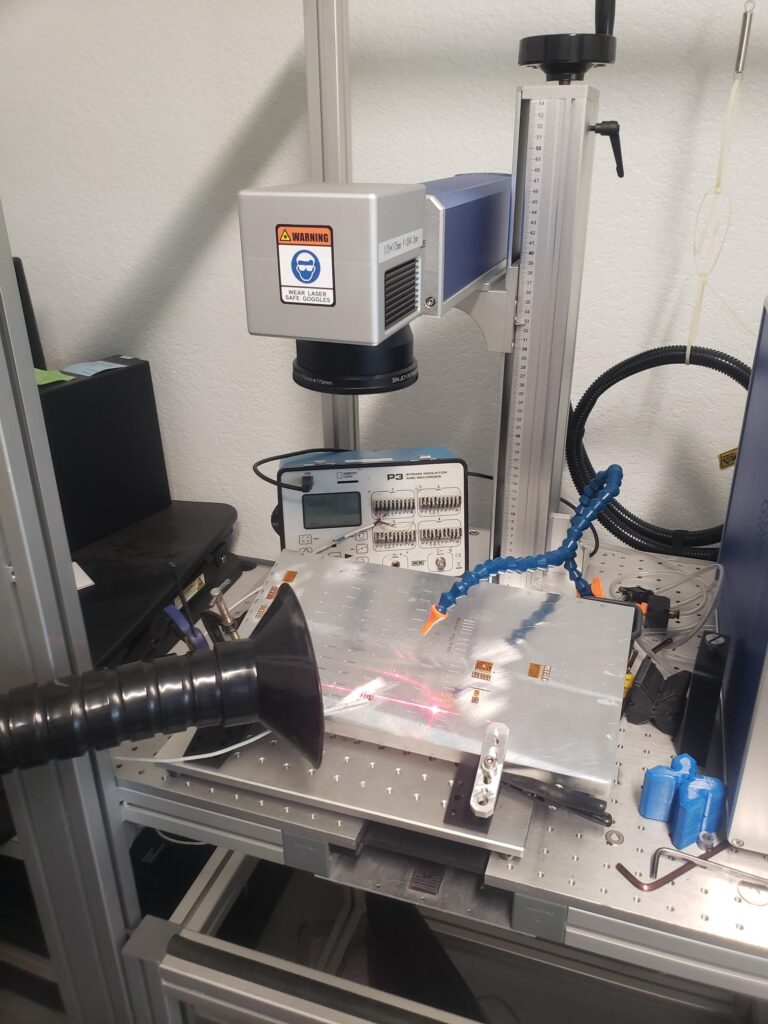

Continue reading Overcoming Challenges in Residual Stress Measurements on Small Test Specimens Using the Slitting MethodHill Engineering Acquires New SFX Laser Engraver

Hill Engineering has recently acquired the state-of-the-art JPT MOPA M7 Laser Engraver with a 175x175mm lens and an 80mm Rotary Axis. This strategic investment will improve our laboratory capabilities, enabling us to deliver unparalleled results to our clients!

Continue reading Hill Engineering Acquires New SFX Laser EngraverNew publication: Effects of high‑energy laser peening followed by pre‑hot corrosion on stress relaxation, microhardness, and fatigue life and strength of single‑crystal nickel CMSX‑4® superalloy

Hill Engineering recently published new collaborative research in the International Journal of Advanced Manufacturing Technology titled Effects of high‑energy laser peening followed by pre‑hot corrosion on stress relaxation, microhardness, and fatigue life and strength of single‑crystal nickel CMSX‑4® superalloy and appears in International Journal of Advanced Manufacturing Technology. The abstract text is available here along with a link to the publication.

Continue reading New publication: Effects of high‑energy laser peening followed by pre‑hot corrosion on stress relaxation, microhardness, and fatigue life and strength of single‑crystal nickel CMSX‑4® superalloyPresentations at TMS 2023 Annual Meeting & Exhibition!

Hill Engineering recently co-authored presentations at the TMS 2023 Annual Meeting & Exhibition in San Diego, CA on March 19th through the 23rd. The TMS Annual Meeting & Exhibition brings together more than 4,000 engineers, scientists, business leaders, and other professionals in the minerals, metals, and materials fields for a comprehensive, cross-disciplinary exchange of technical knowledge. The abstracts for the presentations that we co-authored are copied below.

Continue reading Presentations at TMS 2023 Annual Meeting & Exhibition!New Vlog: How To Apply A Strain Gage

Strain gages feature in a large portion of the residual stress measurements we perform at Hill Engineering, which is why we pride ourselves on our ability to correctly choose and apply strain gages to fit any measurement needs.

Continue reading New Vlog: How To Apply A Strain Gage